Information Technology Reference

In-Depth Information

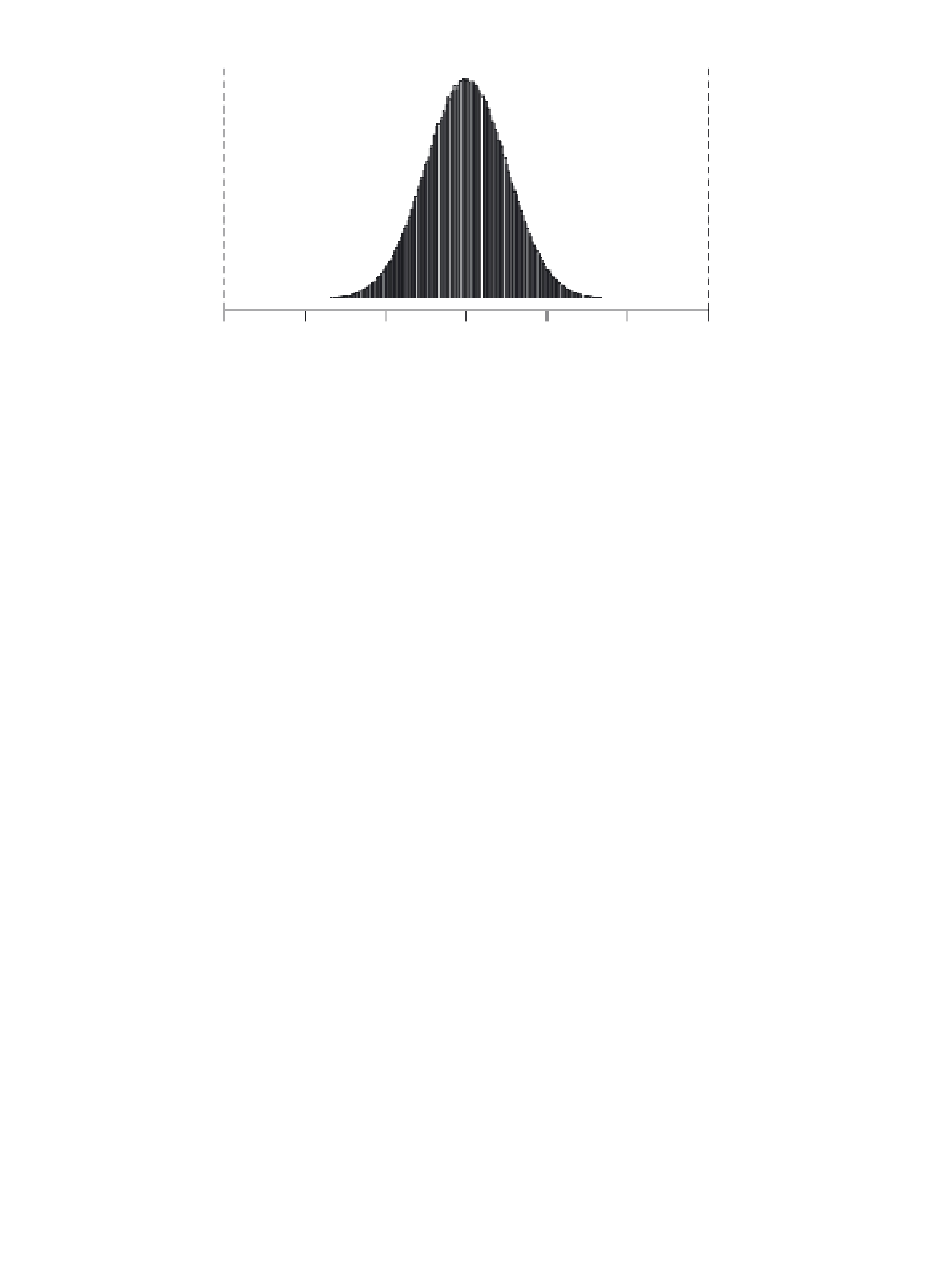

LSL

USL

-6

σ

+6

σ

-6

-4

-2

0

2

4

6

FIGURE 7.9

Highly capable pocess.

deviation. If the process cannot be measured in real numbers, then we convert the

pass/fail, good/bad (discrete) into a yield and then convert the yield into a sigma

value. Several transformations from discrete distributions to continuous distribution

can be borrowed from mathematical statistics.

If the process follows a normal probability distribution, 99.73 % of the values will

fall between the

±

3

σ

limits, where

σ

is the standard deviation, and only 0.27 % will

be outside of the

±

3

σ

limits. Because the process limits extend from -3

σ

to

+

3

σ

,

the total spread amounts to 6

total variation. This total spread is the process spread

and is used to measure the range of process variability.

For any process performance metrics, usually there are some performance speci-

fication limits. These limits may be single sided or two sided. For the A/P process,

the specification limit may be no less than 95 % accuracy. For receipt of material

into a plant, it may be two days early and zero days late. For a call center, we may

want the phone conversation to take between two minutes and four minutes. For each

of the last two double-sided specifications, they also can be stated as a target and as

a tolerance. The material receipt could be one-day early

σ

±

1 day, and for the phone

conversation, it could be three minutes

1 minute.

If we compare the process spread with the specification spread, we can usually

observe three conditions:

±

Condition I: Highly Capable Process (see Figure 7.9). The process spread is

well within the specification spread.

6

σ<

(USL

−

LSL)

The process is capable because it is extremely unlikely that it will yield

unacceptable performance.

Search WWH ::

Custom Search