Biomedical Engineering Reference

In-Depth Information

30

9 nm

Bacterial spores control

Bacterial spores treated

20

0 nm

10

Bacteria control

Bacteria treated

0

500 nm

0

50

100

Displacement (nm)

150

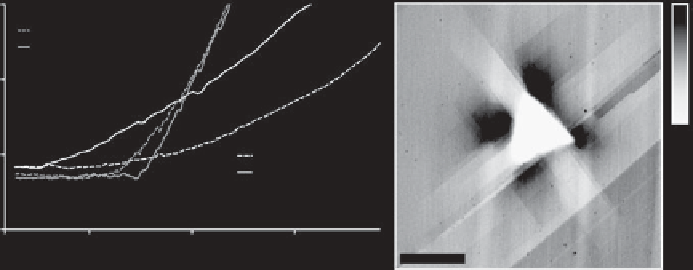

Fig. 3.17. Examples of nanoindentation measurements with the AFM. Left: force-distance curves

measured with the AFM on individual bacteria. Black curves: typical data measured on untreated

and treated

Bacillus

vegetative bacterial cells. Red curves: data measured on

Bacillus

spores.

The data showed that the treatment made the cells softer, but the spores were much harder than

the vegetative cells [178]. Right: AFM image of an indentation made by a dedicated nanoindenter.

The indentation is in a magnesium oxide crystal, and the image shows the indentation (black

triangle) pile-up - material pushed out of hole (white features at triangle corners), and also shows

long-range dislocations in the crystal structure (diagonal discontinuities) [179]. Reproduced with

permission from [180] and kind permission from Dr C. Tromas.

for example individual micro-organisms [169, 183] (see Figure 3.17), living cells

[176, 184] or micro/nanoparticles [185-187]. Some more examples of applications of

nanoindentation are given in Chapter 7.

3.2.3 Mechanical property imaging

Nanoindentation is a very useful technique for mechanical characterization because of the

possibility to collect truly quantitative data on the mechanical resistance of samples. However

it has several drawbacks, including the complicated data analysis, and its relatively slow data

acquisition. The very low rate of data acquisition compared to normal imaging AFMmodes is

a major drawback. For an image with 512

512 data points, a full set of nanoindentation data

would require many hours to collect, leading to problems with thermal drift of the sample. For

this reason 'imaging' type studies with nanoindentation tend to be used only at very low

resolutions (100

100 data points or less). One way to overcome this limitation is to measure

the interaction of the probe with the sample surface while it acquires topographical data, and

use this information to derive mechanical information about the sample surface. This has two

advantages, firstly, data is acquired at a much faster rate, and secondly, the mechanical

information collected may be correlated directly with the measure topography. There are a

number of modes which acquire mechanical information about the sample surface in this way,

and they are described in the following sections.

3.2.3.1 Lateral force microscopy

As described in Section 3.1.1, in contact mode, the vertical deflection of the cantilever,

measured as the difference in signal between the top and the bottom of the split photodiode,