Biomedical Engineering Reference

In-Depth Information

200

RTV11 Feature

RTV11 Flat

Steel

100

0

-500

0

1000

2000

Distance / nm

Topography

Indentation

Max Topo : 1361.2 nm

Min Topo : 0 nm

Max Indent : 620 nm

Min Indent : 0 nm

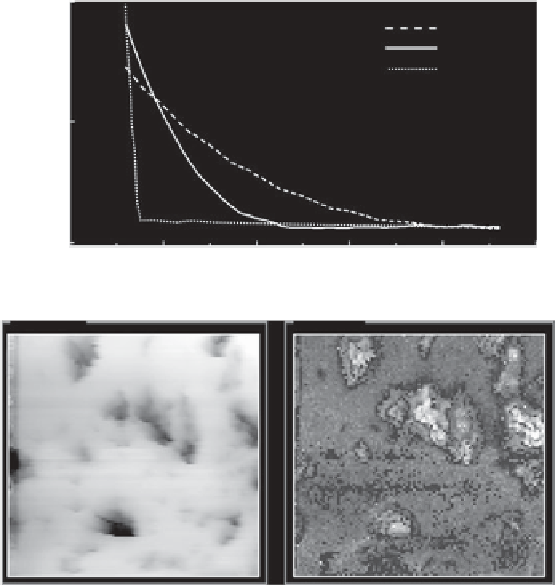

Fig. 7.4. Examples of nanoindentation experiments on a heterogeneous polymer surface. The

sample is RTV11, a silicone polymer with calcium carbonate filler particles. The upper graphs

show force-distance curves on a flat and a raised region of the RTV11, along with a steel surface for

comparison. Below are shown how these experiments may be made in a spatially resolved way. Both

topography and indentation images were derived from a map of force-distance curves acquired in a

10

m square area of the polymer surface. The correlation between the white protruding features in

the topography and dark, hard features in the indentation map suggest that these features correspond

to the hard filler particles [158].

were made of the polymer surface via a force-curve mapping routine. This technique

acquires force curves at user-defined spatial intervals over a user-defined area of the

surface. In this case, 100

m square area, i.e.

curves were acquired every 100 nm. Note that even at this low resolution, such an

experiment can be quite lengthy - if curves were acquired at 1 Hz, the 10,000 curves

would require almost three hours to record. Examples of the force curves obtained are

shown in Figure 7.4. It can be seen that there was considerable heterogeneity on the data

from different parts of the sample surface. In particular, when measuring curves over the

raised features seen on the surface, they were shown to be considerably stiffer than the

surrounding polymer matrix, as is seen in the image of indentation distance (Figure 7.4,

bottom right). Interestingly, a softer region seems to surround each hard particle, possibly

indicating some problems at the matrix-filler interface. These softer interphase domains

100 curves were acquired over a 10