Biomedical Engineering Reference

In-Depth Information

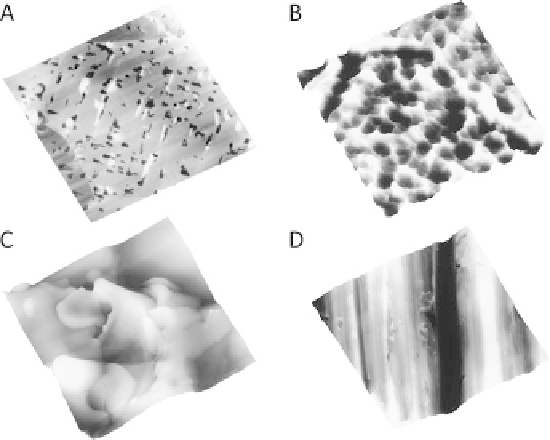

Fig. 7.2. AFM height images of titanium surfaces subjected to various treatments. Samples were

treated by A: polishing with colloidal silica, B: polishing followed by acid etching, C: sandblasting

then treating with air plasma, and D: grinding with silicon carbide paper. Adapted with permission

from [411]. All images have an

X-Y

scale of 20

20

m, and a

z

scale of 6

m.

measure with AFM, due to the fact that AFM produces high contrast on relatively flat

surfaces, and produces three-dimensional, digital data by default. In contrast, scanning

electron microscopy often gives the impression that surfaces with roughness values less

than 10 nanometres are extremely smooth and featureless, due to the fact that SEM detects

electrons scattered from a few nanometres into the surface. On the other hand, optical

techniques are limited in resolution, and require opaque surfaces. AFM has no such

restrictions in terms of samples, and gives accurate values for surfaces with roughness

down to the level of atomic flatness. In addition, neither SEM nor optical microscopy can

directly supply data suitable to measure roughness parameters, but determining roughness

parameters from AFM data is extremely simple. Therefore, AFM has become the method

of choice to measure nanoscale roughness, and is routinely applied to determine roughness

of metals and metal oxides [406], semiconductors [407], polymers [408], composite

materials [158], ceramics [409], and even biological materials [398, 410].

An example of the use of such measurements is the imaging of titanium, one of the

most commonly used materials for many medical implants. Because of its technological

importance, and because the surface texture and roughness of the implant is very

important for its performance, there have been many studies of titanium and titanium

oxide surfaces by AFM [366, 406, 411-414]. For example, in the study by Cacciafesta

et al

., a series of titanium surfaces with different treatments were compared by AFM

[411]. Some example images, of these surfaces are shown in Figure 7.2. The results

showed that roughness varied enormously with surface treatment. Clearly, examination

of the images shown in Figure 7.2 can give some important information on its own; for

example while the polished sample shown in Figure 7.2A displays many pits, it is