Biomedical Engineering Reference

In-Depth Information

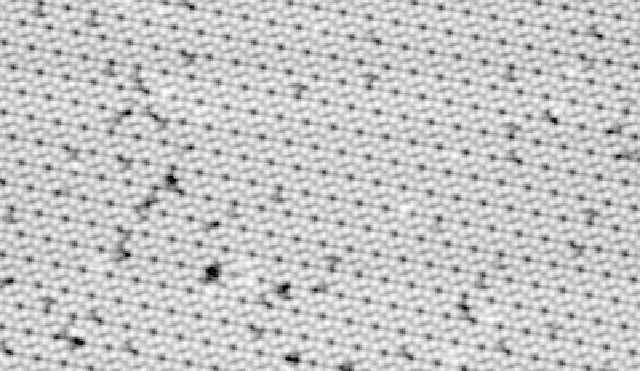

Fig. 1.4. Example of an STM image with atomic resolution. The image shows an atomic-resolution

image of the 5

5 reconstruction of the Si(111) surface. Individual atoms, defects and vacancies are

visible. Reproduced with kind permission from Dr. Randall Feenstra.

Despite the amazing results obtained with STM, the limitation to conducting samples

led the inventors to immediately think about a new instrument that would be able to image

insulating samples. In 1986 Binnig, Quate and Gerber published a paper entitled 'Atomic

Force Microscope' [18, 19]. In that paper they described how they replaced the wire of a

tunnelling probe from the STM with a lever made by carefully gluing a tiny diamond onto

the end of a spring made of a thin strip of gold. This was the cantilever of the first AFM.

Although the first instrument was used only for a few experiments, the results produced

had such great impact that the first instrument now resides in the science museum in

London. The movement of the cantilever was monitored by measuring the tunnelling

current between the gold spring and a wire suspended above it. This set-up was highly

sensitive to the movement of the probe as it scanned along the sample, again moved by

piezoelectric elements. In their paper, Binnig

et al

. proposed that the AFM could be

improved by vibrating the cantilever above the surface [20]. Thankfully nowadays we

don't have to glue tiny diamonds onto gold levers to carry out AFM, but this first

instrument led to the whole field of AFM. The instrument, and the first image recorded

in AFM, are shown in Figure 1.5.

The AFM caused a revolution. Suddenly, with a relatively cheap and simple instrument,

extremely high-resolution images of nearly any sample were possible. While initial

images, such as that shown in Figure 1.5, did not have as high resolution as STM,

atomic-resolution images were soon reported [21]. Soon after the invention of the AFM,

the gold leaf/diamond combination was replaced by much more reproducible cantilever

manufacture by silicon lithography, which enables the production of more than 400

cantilevers on a single 7-inch wafer [22]. Furthermore, it was quickly realized that simpler

methods than the STM could be used to detect the motion of the cantilever. Nowadays,

most AFMs use a light lever to sensitively detect the motion of the cantilever, this method

is considerably simpler than the STM set-up, allows for larger cantilever motions, and is