Environmental Engineering Reference

In-Depth Information

important to note in any fuel cell stack that owing to the low voltage per cell of

1.23 V

oc

(~0.6 V loaded at peak power), many repeat units are necessary in a stack

in order to develop appropriate voltage levels for hybrid traction. A typical stack

may consist of 50 repeat units or more.

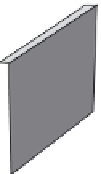

Membrane electrode

assembly

O

2

Gas flow channels

H

2

H

2

Endplate

O

2

Bipolar plate

Repeat unit

Figure 10.47 Basic PEM fuel cell stack construction (3M Corporation)

Note in Figure 10.47 that the gases must flow through the entire stack. A

counter-flow scheme is depicted here that has oxygen (air) entering on the left and

dry hydrogen entering on the right. The hydrogen is already under pressure when

compressed gas storage is used and the inlet hydrogen is regulated down to fuel cell

stack pressure (i.e. 10-250 psig), and typically 300 kPa (44 psi) in a PEM stack. In

order to overcome stack flow restrictions, the air must be compressed prior to being

fed to the stack inlet. Typical fuel cells may have a 10 kW or higher power air

compressor running to maintain air feed and flow. The PEM fuel cell is a low-

temperature device operating at less than 200

C, typically at 80

C.

The basic PEM fuel cell reactions consist of electron release from hydrogen at

the anode (negative electrode) and recombination at the cathode (positive electrode

or terminal). The overall reaction is the combination of hydrogen and oxygen to

produce water:

H

2

!

2H

þ

þ

2e

1

2

O

2

þ

2H

þ

þ

2e

!

H

2

O

ð

10

:

67

Þ

1

2

O

2

!

H

2

O

H

2

þ

The electrolyte used differentiates the various types of PEM fuel cells, also

called solid polymer electrolyte fuel cell. The electrolyte is a substance that dis-

sociates into positively and negatively charged ions in the presence of water,

making it electrically conducting. Polymer electrolytes, such as Nafion (DuPont