Environmental Engineering Reference

In-Depth Information

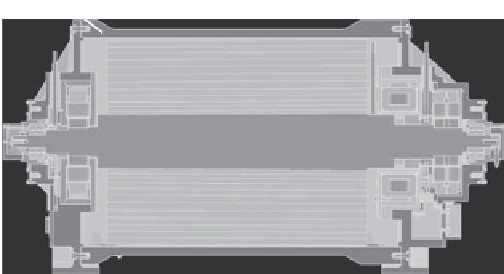

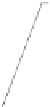

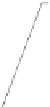

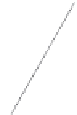

Flywheel

housing

Composite flywheel

Balance holes

Damper

and

backup

bearing

Magnetic bearing

sensors

Radial magnetic

bearing

Rotor axial

position

sensor

Magnetic

bearing

sensors

Combo

magnetic

bearing

End plate mount

Phase angle

sensors

Composite banding for

motor/generator section

Motor/generator

rotor magnets,

back iron

Titanium

rotor

shaft

End plate/mount

Figure 10.42 Flywheel energy storage system (from Reference 30)

withstanding the hoop stress resulting from centrifugal forces are - as is the case

with electrochemical batteries - the lightest materials available having the highest

tensile stress. This is because the hoop stress grows in proportion to the density of

the material used, whereas stored energy grows as the square of angular speed. A

lightweight material flywheel will store the same energy as a steel flywheel but

weigh less. The amount of energy stored in a flywheel is equal to one-half the

tensile stress at the bursting point of the rim material divided by its density.

Mathematically this is expressed as

K

mx

2

r

E

FW

¼

(Wh

=

kg)

ð

10

:

66

Þ

where

K

mx

is the limiting tensile stress at which point the rim will delaminate or

burst. Fibres that offer the highest energy storage density are derived from E-glass,

which can store four times as much energy as high strength steel. Kevlar, an aro-

matic polyamide, derived from nylon can store seven times the energy of high

strength steel. Probably the best choice of fibre is fused silica glass, which can store

up to 15 times the energy of the best alloy steel. A flywheel energy storage unit

will be far lighter than an electrochemical battery. Estimates of energy storage

for electric vehicles centre on 30 kWh to provide a 200 mi range at reasonable

speeds (55 mph in North America). A lead-acid battery rated 30 kWh would weigh

1,000 kg, and a fused silica flywheel would come in at 60 kg plus the electric drive

system to charge/discharge the unit. If the power electronics and drive motor could

tolerate the power level, this 30 kWh flywheel could be recharged in 5 min.

The real advantage of flywheel energy storage is the high rate of energy input

and release possible. This is particularly advantageous on regenerative braking.

Flywheel energy storage is now being used extensively in electric rail applications

as energy storage stations near stops in lieu of adding more utility substations. The