Environmental Engineering Reference

In-Depth Information

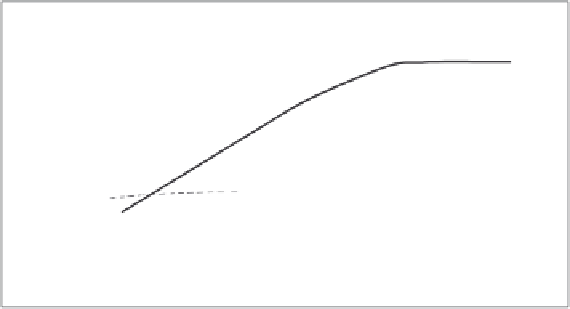

More recently there has been experimental work on comparing the pulse dis-

charge characteristics of a lithium ion battery with a high power ultra-capacitor [8].

The graphic in Figure 10.17 compares a commercial 12 Ah lithium ion cell versus a

production 3,000 F, 2.7 V ultra-capacitor cell in the ability to capture regeneration

energy in an HEV and then discharge it back into the vehicle system. Notice that at

100 s the lithium cell will capture five times more energy than the ultra-capacitor

and return this with relatively high efficiency (the dotted trace). However, at 10 s

both capture the same energy, but the ultra-capacitor discharges this back at

>

95%

efficiency whereas the lithium ion can only discharge 50%. Therefore, for 10 s

power the ultra-capacitor is twice as effective as the lithium ion in cyclable energy

transfer. It is also evident that the ultra-capacitor applicability extends up to 20 s

versus lithium ion.

1,000

b

a

tt

ery

100

captured

capacitor

10

stored

1

1

10

100

1,000

10,000

Charging time (s)

Figure 10.17 Energy shuttling comparison of lithium ion versus ultra-capacitor

( from Reference 8 with permission)

Today there are considerable varieties of lithium cell chemistries, most deal

with replacing expensive cobalt in the cathode active material with less expensive

elements such as nickel, aluminium, manganese, iron vanadium and to a lesser extent

with the types of conductive and binding agents used [9]. To improve safety, by

enhancing thermal stability, iron, magnesium and copper are used. Non-graphite

anodes continue to receive significant attention with Li

4

Ti

5

O

12

for improved safety

and Li

1.1

V

0.9

O

2

for improved capacity. For any of these cell types, cost is driven to a

first order by the separator material with polymers, ceramics, non-wovens and metal

oxide composites. Alternate materials for the separator section include natural as

well as synthetic materials. For natural separators, the products are mostly cellulose

products or their chemically modified derivatives. For the synthetic counterparts,

polymers of many types including nylons, polyolefins, PTFE and polyamides (to

name a few) are used, as well as synthetic inorganic forms such as ceramics and