Environmental Engineering Reference

In-Depth Information

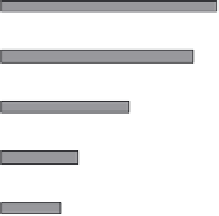

Table 9.1 Fuel cycle upstream energy consumption and CO

2

emissions

( from Reference 5)

Fuel type

Upstream total

energy (J/MJ)

Upstream

CO

2

(g/MJ)

Gasoline

262,049

18.5

Diesel

197,654

14.1

E85 (15% gasoline, 85% ethanol)

561,759

12.2

Electricity

3,261,902

195.1

Gaseous H

2

634,356

92.0

Liquefied H

2

1,484,523

138.5

from 100% corn stock with the caveat that the US is unlikely to produce corn in

sufficient quantity to meet large scale transportation needs. Transportation fuel

consumption in North America accounts for some 40% of all energy usage. Second,

in terms of emissions of CO

2

, E85 has a negative result because in the process of

growing, corn absorbs CO

2

from the atmosphere. Third, electricity in the context of

a BEV makes sense from a TTW perspective, but clearly its upstream energy and

emissions are very significant.

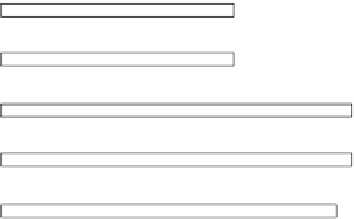

Figure 9.2 summarizes the total energy scenario from primary fuel to energy

available at the vehicle's wheels in the two step process noted above: WTT

and TTW, plus a composite energy for well-to-wheel (WTW). The CIDI hybrid

vehicle has higher overall efficiency than a conventional CIDI power plant vehicle

because of the hybrid's energy regeneration capability. The same applies to the

difference noted between a conventional, or direct hydrogen, FCV versus a hybri-

dized fuel cell vehicle (FCHV).

Figure 9.2 shows that gasoline and diesel fuel have the highest WTT effi-

ciency, consistent with their production energy consumption listed in Table 9.1, but

Fuel cycle efficiency

55.9

H

2

FCHV

52

29.1

55.9

H

2

FCV

46.6

WTT

26.1

84.3

CIDI HV

31

TTW

26.1

84.3

WTW

CIDI ICE

18.5

15.6

80.6

Gasoline ICE

14.1

11.4

0

20

40

60

80

100

Efficiency (%)

Figure 9.2 Well-to-wheel energy efficiency summary (modified from Reference 4)