Environmental Engineering Reference

In-Depth Information

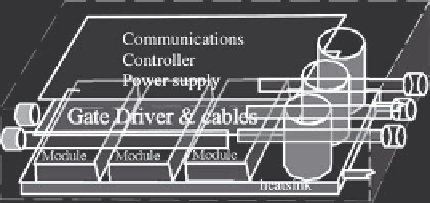

PNGV's automotive integrated power

electronic module (AIPM) program:

Component

% total $

Control/comm/ps

13

Gate dr/modules/cable

30

Die cast/heatsink conn

33

Bus bars/curr sen/caps

24

100

Figure 6.22 Power electronic inverter package for hybrid M/G applications

inverter component costs for a 300 V, 40 kW and a 42 V, 10 kW design. Note that

the system currents in both designs are nearly equal and the relative costs are

almost same, yet the total power throughputs are vastly different.

Future trends in IPEM design may expand on technology invented at the

General Electric and referred to as power overlay [18]. Power overlay is basically a

thin film multi-chip process for power modules. With this technique rather than

bonding chips to the top of a multi-layered substrate of interconnects, the chips are

embedded into the interconnected layers. Wire bonds are eliminated by use of

vertical interconnect access (vias) through the insulating layers connecting metallic

surface of the chip pads.

Investigations are on to increase the operating temperature of power electronic

and control electronic modules. Temperature ranges of interest are up to 200

C for

low band, from 200 to 300

C for medium band, and

>

300

C for high band.

The low band silicon-on-insulator (SOI) appears to show promise and some appli-

cations are in use today, but not for power. Power semiconductors are not adequate

for operation above 200

C; to exceed this temperature, devices with wider energy

Percent inverter cost breakout by subassembly

50

40 kW/300 V

10 kW/42 V

40

30

20

10

0

Figure 6.23 Cost cascade of 300 and 42 V power inverters