Environmental Engineering Reference

In-Depth Information

60

°

45

°

F

F

(a)

(b)

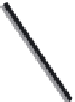

Figure 5.51 Pole change PM machine in 8-pole (left) and 6-pole (right)

configurations ( from Reference 33): (a) PCPM machine having four

magnets/pole in an 8-pole configuration and (b) PCPM machine in a

6-pole configuration (one magnet remains un-magnetized, shown in

white with black dots)

In recent years, some dramatic improvements over that concept have come to light

[33,34]. In the work by Prof Ostovic, it is proven that discrete speed control is achievable

in permanent magnet machines via control of stator current so that such machines can be

operated at discrete speeds in much the same manner as squirrel cage IMs.

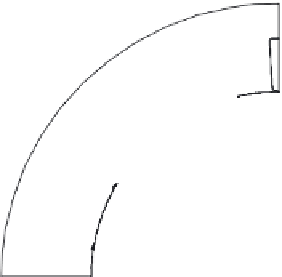

Initially, all 32 of the permanent magnet slabs in Figure 5.51 are magnetized

tangentially and oriented such that pole flux exits the soft iron rotor wedges as

shown. Next, suppose the prior 8-pole stator winding is reconfigured electronically

using the techniques described for PPM into a 6-pole stator. Next, a short pulse of

magnetizing current is fed into the stator windings that re-magnetizes the rotor

magnets into the 6-pole pattern illustrated in Figure 5.51(b). Since 32/6 is not an

integer, some of the magnets in the 6-pole configuration remain non-magnetized;

one such magnet is shown in Figure 5.51(b).

In another variation on the PCPM, the magnet polarization is modulated so that

true field weakening can be achieved. This is possible in the 'memory' motor or,

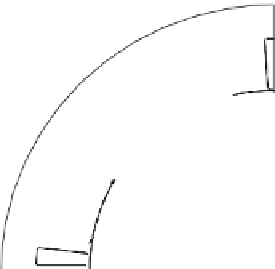

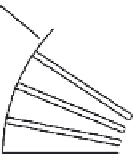

more appropriately, variable flux memory motor (VFMM). In Figure 5.52 the

variable flux PM machine is shown in a full flux state (a) and at partial flux (b).

Note that in Figure 5.52, when under partial magnetization, portions of the per-

manent magnets become reverse magnetized so that the net field entering the airgap is

diminished. This feature of the VFMM yields efficient field weakening by a short

pulse of stator current. This machine in effect combines the high efficiency of a PM

machine with the airgap flux control of a wound field synchronous machine. The rotor

magnets can be bonded rare earth, ferrite, or in this special class of machine, Alnico.

Alnico is relatively easy to magnetize and re-magnetize and at the same time a high

flux magnet. The rotor geometry is amenable to such magnets and the flux squeezing

design means that very high airgap flux can be realized. It is anticipated that CPSRs

of

>

5:1 can be achieved with this class of machine. This is particularly important for

hybrid propulsion systems, ancillary systems control and other applications.