Environmental Engineering Reference

In-Depth Information

architectures require the traction motor to operate well into field weakening,

particularly in fuel cell architectures having a single gear reduction between the

traction motor and wheels, (2) safety reasons so that over-speeding the traction

motor by the engine in a gasoline-electric hybrid will not backfeed the dc link in

the event of loss of

d

-axis current regulation by the inverter. Concurrent with this

requirement is the corollary that the IPM does not develop braking torque should

the inverter switches all turn off, regardless of speed and (3) a weak magnet IPM is

more cost-effective because ferrite magnets, bonded rare earth and other ceramic

magnets are sufficient to provide the

d

-axis magnetization needed. The conditions

stated in condition (2) above are also known as uncontrolled generation (UCG)

mode and represent a significant design constraint on the application of IPMs in

traction drives.

The following subsections will treat the various IPM designs in more detail

based on the above constraints for vehicle hybrid propulsion systems.

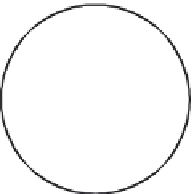

5.3.1 Buried magnet

The most common IPM machine has the rotor geometry of the original buried

magnet design. This single buried magnet layer design is illustrated in Figure 5.22

along with a dimensioned magnet slab for reference.

q

y

m

L

m

D

m

d

W

m

Permanent magnet

Figure 5.22 Original buried magnet rotor design

In Figure 5.22 the magnet length,

L

m

, is its thickness in the direction of mag-

netization. Each face of the buried magnet is aligned with the rotor

d

-axis so that

alternating north and south poles are equally spaced about the rotor circumference.

The interpolar gap of a buried magnet IPM is filled with soft iron as shown in

Figure 5.22 along the machine's

q

-axis. The magnet slabs themselves are most

suitably inserted into the rotor magnet cavities in an as-pressed state so that no

additional machining is required during assembly. Ceramic magnets (barium and

strontium ferrite) are easily magnetized in situ. Rare earth magnets, including

bonded rare earth, are best pre-magnetized and then inserted into the rotor cavities.