Environmental Engineering Reference

In-Depth Information

1 cm

Ferrite magnet

rotors

Coiled iron core made

of amorphous metal

(a)

(b)

(c)

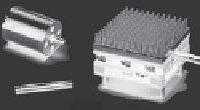

Figure 5.4 Novel electric machines: (a) amorphous iron (Hitachi motor), (b) very

high speed machine (1M rpm PM machine) and (c) concentrated

winding servo motor

The Hitachi machine shown in Figure 5.4 was built by Hitachi Industrial

Equipment Systems Co. Ltd with a core of amorphous metal and ferrite magnet rotor.

It does not require neodymium or dysprosium rare earth magnets. Because amor-

phous metal is a supercooled liquid, its disordered atomic structure, versus crystal-

line structure of steels, provides high tensile strength and low magnetic losses.

Researchers at ETH Zurich, and later the company Celerotron, fabricated such

titanium-encapsulated rotor, and special ball bearings facilitated this extreme speed

machine. The prototype shown in Figure 5.4 is of the size of a small matchbox.

The concentrated winding stator shown is typical of such designs. Here, an

m

¼

3

phases,

Q

¼

9 slots and

P

¼

6 poles having a slots/pole/phase (SPP)

¼

Q

/

mP

¼

1/2.

5.1.3 Rare earth permanent magnets

The NdFeB permanent magnet has been discussed in previous sections in terms of

energy and its relation to other types of magnets. In this section, some detail of

NdFeB in regard to electric machine use is cited. In particular,

NdFeB rare earth magnets have high electrical conductivity and will therefore

experience higher rotor heating from PWM drives than lower conductivity

magnets such as ceramics and ferrites.

●

The rare earth magnet is also very dense, close to the density of iron and as

such is subject to corrosion in humid environments. This has led to a need to

coat the magnet with nickel and aluminium. Earlier designs relied on herme-

tically sealed cans to cover the NdFeB magnets. Otherwise, they would slowly

disintegrate and rust away.

●

It is typical of RE magnet use to have smaller slabs cut and insulated from each

other to minimize eddy current heating on the rotor. There is still interest in

using bonded RE magnets because of their low cost, but the very low energy

product (see the lower right box in Figure 5.3) has been a performance deterrent.

●

The real advantage of NdFeB in addition to very high energy product and high

remanence is its very high coercivity. This is a strong advantage in electric

machines so that demagnetization due to armature (stator) reaction will not

occur, even at higher temperatures.

●