Environmental Engineering Reference

In-Depth Information

Table 4.4 Types of automatic transmissions

Manufacturer Transmission Mass Application Architecture Unique

features

Aisen AW

55-50SN

89 kg

FWD

Simpson

Double pinion

epicyclic gear

5-speed

Aisen AW

A750E

89 kg RWD

Simpson

Double planet

epicycle gear

5-speed

ZF

6HP26

84 kg RWD

Lepelletier

Ravigneaux

gear set

6-speed

Integrated

TCU

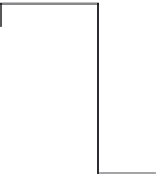

In Figure 4.4, clutches (Cs), brakes (Bs), and one-way-clutches (OWC, Fs) are

shown schematically tied to the transmission case with ground symbols. The main

shaft (input) and counter shaft (output) are lines of symmetry in the schematic. Clutch

C1 is always the transmission input clutch on the turbine side of the torque converter.

The torque converter impeller and turbine are locked via the lock-up clutch (L/U).

Electrical connections to the M/G are via the stator of the electric machine

packaged around the torque converter. The M/G rotor is mounted to the torque

converter at the flex plate (impeller) and aligned with the torque converter into a

finished assembly at the torque converter assembly plant. M/G rotor encoder

assemblies would also be mounted and aligned at the torque converter plant. The

Electrical

B3 F2 B2 B1

Stator

LUC

C2

C1

Rotor

R2

C2

C11

C11

S11

S11

Input

F1

B5 B4

C3

Output

Figure 4.4 Simpson type stepped automatic transmission