Biomedical Engineering Reference

In-Depth Information

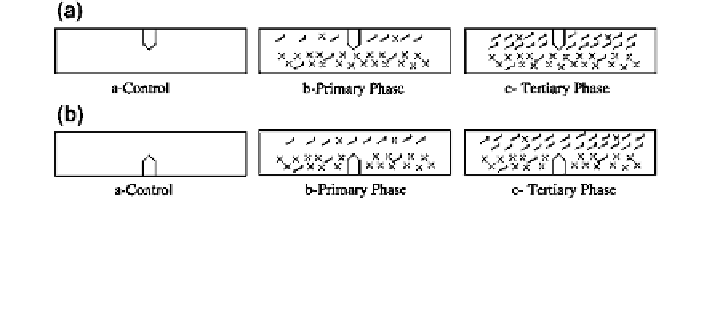

Fig. 6 A schematic representation of microdamage morphologies and their relationship to an

artificially introduced notch on the a compressive and b tensile sides of specimens subjected to

bending fatigue to the primary and tertiary phases of modulus loss. ''x'' and ''-'' represent

diffuse damage and linear microcracks, respectively. Reprinted from permission with Elsevier

[

10

]

mostly from their resistance to crack propagation rather than initiation only

[

62

-

64

].

Thus, in contrast to focusing on microdamage that initiates and accumulates

with age, recent studies have focused more on the ability of bone to resist prop-

agation. In particular, several crack propagation studies have been conducted in

which propagation toughness has been measured using a fracture mechanics

approach [

7

,

45

,

62

,

65

]. Results show that discrete microcrack formation occurs

behind the tip of a propagating fracture crack (frontal process zone) that dissipates

energy and decelerates the advancing fracture [

7

,

63

]. The frontal process zone

develops into a region of microcracks surrounding the propagating fracture

(process zone wake), and both regions absorb energy during loading and lead to

increased crack growth resistance [

29

,

45

,

62

,

63

]. Energy dissipation through

microcracking may breed into other toughening mechanisms such as uncracked

ligament formation and crack deflection [

65

]. It is likely that the formation of

uncracked ligaments involves microdamage that arrests a propagating crack and

initiates a new crack [

66

]. Hence, microdamage forms during crack propagation

(de novo microdamage) and plays a significant role in determining bone's

toughness [

63

]. Consequently, increased bone fragility with age may also be due in

part to bone's decreased ability to form de novo microdamage. Additional studies

are needed to examine this possibility.

Consistent with the above concepts, it has been shown that under fatigue

loading, cortical bone forms and compartmentalizes microdamage in order to

dissipate energy (Fig.

6

)[

10

]. During the primary phase, diffuse damage formed

on the tensile side while few linear microcracks formed on the compressive side.

Furthermore, specimens notched on the compressive side accumulated more

microdamage near the notch and had high toughness. In contrast, specimens

notched on the tensile side had low toughness since the region was already filled

with diffuse damage. Continued loading of specimens into tertiary phase caused

significant accumulation of linear microcracks on the compressive side. More

Search WWH ::

Custom Search