Graphics Reference

In-Depth Information

to its limits, and alerts (such as a fault in a mechanical compressor). The

alert-based system provided one way to easily monitor the system: no alerts

equals no problem.

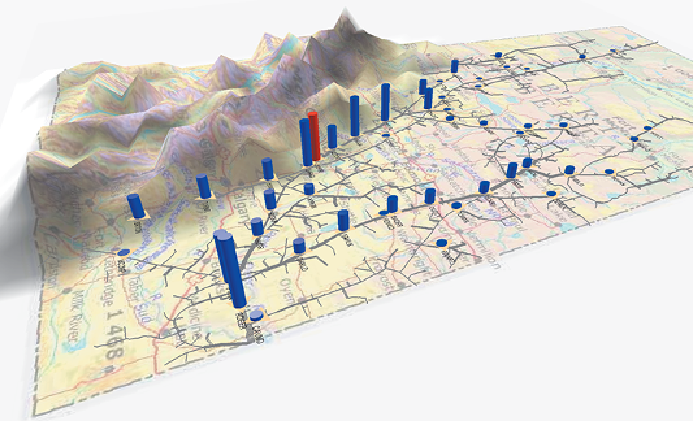

The solution provided was a graph visualization roughly along the lines of

theoneshownin

Figure 1-7

.

Thelinks weresized basedonpipeline capacity,

with nodes indicating flow through the station as a 3D bar, colored the node

based on the limits (for example, blue for not close to limit and red for close

to, or exceeding, limit), and added a significant red flag on top of the node if

an alert was triggered.

Figure 1-7:

As shown in this pipeline graph, gas generally flows from the

north (top of image) to the south (bottom left).

One interesting incident occurred shortly after we had completed an early

version of the visualization. The alert system had no active alarms. But

the visualization showed one compressor station operating close to it limits

with a high volume going through the station (red in the figure). Inspecting

all the node attributes associated with that station via a tooltip indicated

no particular problems other than the station was working very hard and

close to its limits. Having the whole graph visible meant that the analysts

could visually inspect all the neighboring nodes for clues. One of the nodes