Environmental Engineering Reference

In-Depth Information

C

A

,i

C

A

,i

C

A

,o

C

A

,2

C

A

,o

C

A

,4

C

A

C

A

C

A

,3

C

A

,1

x

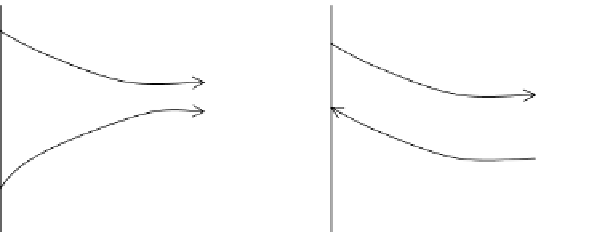

Cocurrent

x

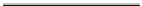

Countercurrent

Figure 2.3

Concentration profiles.

barrier and

C

A

,

4

can be larger than

C

A

,

o

. Therefore, countercurrent operation is usually

the preferred method.

To account for the variation in driving force, a log-mean driving force is used instead

of a linear one:

C

1

−

C

2

ln

C

1

C

2

.

C

lm

=

(2.5)

This equation is derived in Middleman [1].

For countercurrent flow:

C

1

=

C

A

,

i

−

C

A

,

4

(2.6)

C

2

=

C

A

,

o

−

C

A

,

3

.

For cocurrent flow:

C

1

=

C

A

,

i

−

C

A

,

1

(2.7)

C

2

=

C

A

,

o

−

C

A

,

2

.

C

2

are the concentration differences at each end of the barrier. This analysis

will be used in the chapter on membranes (Chapter 9).

C

1

and

2.7

Productivity and selectivity

In the evaluation of a separation process, there are two primary considerations: productivity

and selectivity. The productivity, or throughput, of a process is the measure of the amount

of material which can be treated by this process in a given amount of time. This quantity

is usually specified by the feed flowrate to the process and/or the amount of a product

stream. The selectivity of the process is the measure of the effectiveness of the process

to separate the feed mixture. Selectivity is usually given by a separation factor (

α

ij

),

which is a ratio of compositions in the product streams for an equilibrium process or

Search WWH ::

Custom Search