Environmental Engineering Reference

In-Depth Information

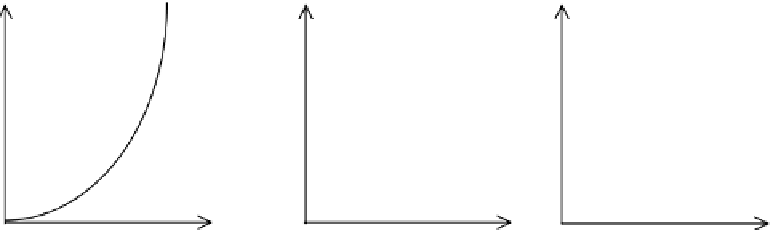

Operating line

I

I

I

Initial

loading

Equilibrium

Clean purge

Actual

F

Equilibrium curve

Actual

Equilibrium

Fluid concentration

Y

Distance

z

Time

t

G

qY

b

Design Equation

:

V

= z

/

t

=

ρ ∆∆

/

b

ρ ∆∆

⋅

qY

G

/

Desorption Time:

t

dt

=

b

L

b

Minimum Purge Requirement:

m

=

G

∆∆kg purge/kg bed

/

qY

Figure 7.10

Type III isotherm: desorption [10].

7.10

Design of fixed-bed adsorption columns

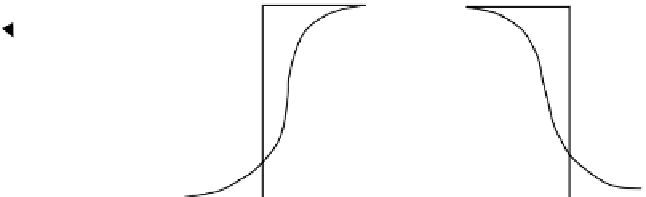

Two macroscopic methods to design adsorption columns are the scale-up and kinetic

approaches. Both methods rely on breakthrough data obtained from pilot columns. The

scale-up method is very simple, but the kinetic method takes into account the rate of

adsorption (determined by the kinetics of surface diffusion to the inside of the adsorbent

pore). The scale-up approach is useful for determining the breakthrough time and volume

(time elapsed and volume treated before the maximum allowable effluent concentration

is achieved) of an existing column, while the kinetic approach will determine the size

requirements of a column based on a known breakthrough volume.

7.10.1 Scale-up approach

Initially, a pilot column with a bed volume (

V

p

) and volumetric flowrate of fluid (

Q

p

)

is used. As shown in Figure 7.11, the total volume (

V

pilo

T

) of fluid that passes through

the column is measured until the outlet solute concentration is observed to rise to the

maximum allowable value (

C

a

).

The (plant-scale) design column should operate such that:

1 Fluid residence time in the pilot and design column are the same.

2 The total volume of fluid processed until breakthrough per mass of sorbent in the column

is the same for both columns.

Search WWH ::

Custom Search