Environmental Engineering Reference

In-Depth Information

q

T

a

q

a

TSA

PSA

T

d

q

d

P

d

P

a

P

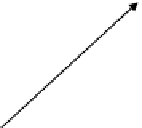

Figure 7.1

Isotherm diagram illustrating pressure-swing (PSA) and temperature-

swing (TSA) processes [5]. Reproduced with permission of the American Institute

of Chemical Engineers. Copyright

c

1988, AIChE. All rights reserved.

relationship). The isotherm should span the concentration range required. If there is a

temperature change, then this information also needs to be available over the temperature

range of interest. These data are needed at both the adsorption and desorption (sorbent

regeneration) conditions. It is usually necessary to change the operating conditions of

the adsorption process during regeneration to make desorption more thermodynamically

favorable. This can involve an increase in temperature and/or a reduction of partial pressure,

and data at these new conditions can be helpful in the analysis.

Figure 7.1 illustrates the data required for the various sorption options. The sorption

isotherm is plotted for two temperatures. For a pressure-swing process (PSA), the adsorp-

tion step is performed at

P

a

and the desorption at

P

d

. The maximum amount of solute

removed and recovered per mass of sorbent is

q

a

−

q

d

. The temperature-swing process

(TSA) is also illustrated. A combination of temperature and pressure swings can be used,

although this is rarely done in practice. Note that the absolute values of the pressure and

temperature as well as the change (swing) affect the productivity of the process. In addi-

tion, pressure changes can be accomplished very rapidly while temperature changes occur

much more slowly since the entire bed must be heated or cooled. Typical cycle times for

PSA are 1-5 minutes while it is 2 hours or longer for TSA. Once the sorption isotherm

information is obtained, then other factors need to be considered in adsorption design [5]:

1 Sorbent capacity (i.e., how much material is adsorbed per unit quantity of sorbent). The

surface area per unit volume of the sorbent has an important influence on this value. For

this reason, sorbents are usually highly porous materials. Obviously, one would want

the capacity to be as high as possible.

2 The purity requirement of the fluid phase (i.e., how much material needs to be removed).

3 Sorbent selectivity. This can be accomplished by three mechanisms: (a) selective

binding to the sorbent surface (equilibrium); (b) excluding certain components based

Search WWH ::

Custom Search