Environmental Engineering Reference

In-Depth Information

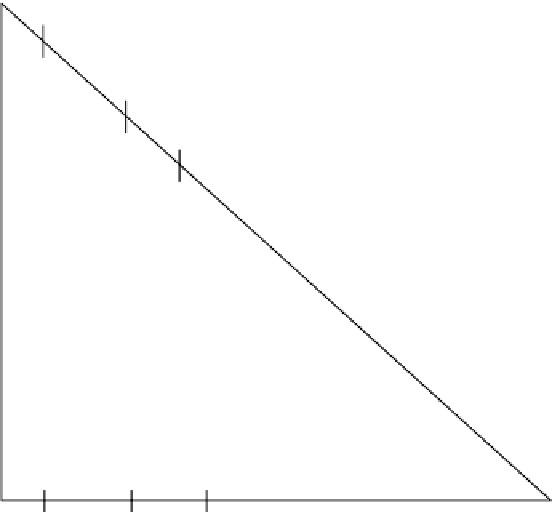

y

A

0

V

0

y

A

2

y

A

1

V

2

V

1

M

2

M

1

O

1

O

0

O

2

x

A

2

x

A

1

x

A

0

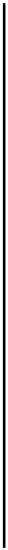

Figure 5.7

Triangular diagram depicting cross-flow cascade.

Example 5.1: cross-flow cascade

Problem:

Acetic acid (vinegar) is a common component in the waste stream of various

fermentation processes. This process represents a significant environmental concern

because the manufacture of pharmaceuticals can result in carboxylic acid-containing

by-products. The carboxylic acid byproducts must be removed from the pharmaceuti-

cal products as well as any water streams prior to discharge. Isopropyl ether has been

used as a solvent for extraction. The isopropyl ether is then distilled and recycled

back to the extraction process. As an example, a feed that is 30 wt% acetic acid and

70 wt% water is fed to a two-stage cross-flow cascade. Feed flowrate is 1000 kg

/

hr,

hr of solvent containing 99 wt% isopropyl ether and 1% acetic acid is

added to each stage. Operation is at 20

◦

C and 1 atm where the equilibrium data are

given in Table 5.1 [2]. Determine:

(a) the weight fractions of the outlet raffinate and the two outlet extract streams;

(b) the flowrate of the outlet raffinate.

Solution:

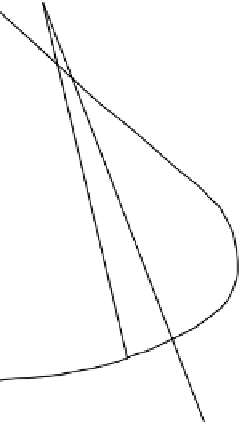

Figure 5.8 is a schematic of the example. Point

O

0

and point

V

0

are plotted on Figure 5.9,

with a line connecting them. The

x

-coordinate of the first mixing point,

M

1

,was found

from the equation:

and 1250 kg

/

Search WWH ::

Custom Search