Environmental Engineering Reference

In-Depth Information

In spray towers the highest rates of mass transfer tend to occur close to the distributor

plates. At small distances above and below the plate the dispersed phase tends to recoalesce

and mass transfer declines significantly, such that it is more effective to add distributors

to redisperse the droplets than to increase the height of the tower. Another solution is to

add packing similar to that used in absorption towers. The packing causes the drops to

coalesce and reform and, thus, reduces the height of each theoretical transfer unit.

The two streams flowing countercurrent creates the possibility of flooding. If the lighter

phase is dispersed and the downward flowrate of the heavier phase becomes too high, the

lighter-phase droplets become held up and exit with the heavy phase through the column

bottom. If the heavier phase is dispersed and the flow of the lighter phase becomes too

high, the heavy-phase droplets become held up on top of the lighter phase and exit the

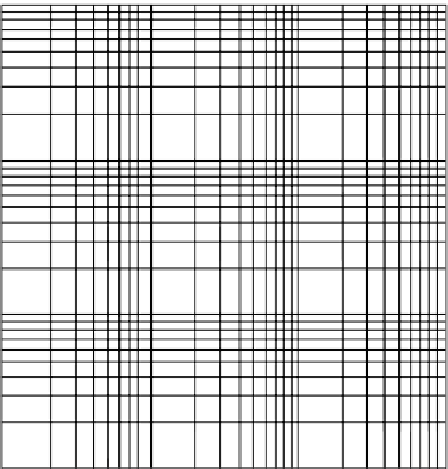

top of the column. Flooding velocity for the continuous phase as a function of that for the

distributed phase can be estimated from Figure 5.3.

V

s

,

d

2

V

s

,

c

+

ρ

c

The

x

-axis is the group

a

v

µ

c

10

4

10

3

10

2

10

10

2

10

3

1

10

2

(

)

V

V

+

ρ

s,c

s,d

c

a

µ

υ

c

Figure 5.3

Flooding velocities in packed extraction towers [1]. L. McCabe,

Unit

Operations of Chemical Engineering

. Reproduced with permission of McGraw-

Hill companies.

Search WWH ::

Custom Search