Environmental Engineering Reference

In-Depth Information

K

'

(a)

(b)

L

'

J

'

Reboil

Reboil

L

y

K

J

x

B

x

F

x

D

x

B

x

F

x

D

x

x

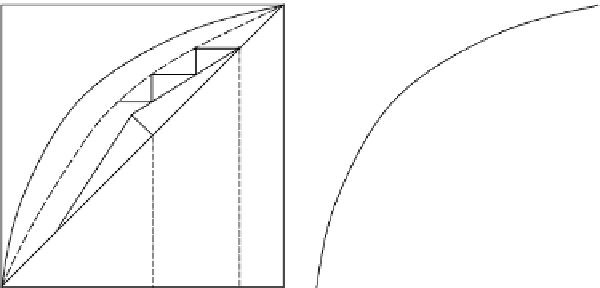

Figure 4.21

Murphree efficiencies: (a) vapor phase, E

MV

, (b) liquid phase, E

ML

.

where

y

n

=

actual composition of

V

phase leaving the stage

y

n

=

composition of hypothetical

V

phase that would be in equilibrium with

L

phase leaving actual stage.

This method is more meaningful than the overall efficiency because it is based on the

difference between true operating and hypothetical equilibrium vapor-phase concentra-

tions. However, Murphree efficiencies also vary from stage to stage and require difficult

measurement of process variables.

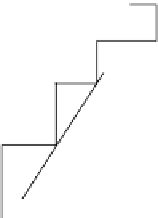

The Murphree ef

ficiency i

s the ratio of distance between the operating line and the

equilibrium line (

=

[

JK

/

JL

×

100]% in Figure 4.21(a)). Similarly, the Murphree liquid

efficiency is given by:

x

n

−

x

n

+

1

E

ML

=

x

n

+

1

×

100(%)

,

x

n

−

[J

K

/

J

L

×

100]% in Figure 4.21(b)).

Note:

Remember that a reboiler is an equilibrium stage, even though the other stages in a

column will not reach equilibrium if they are not 100% efficient. Therefore, the last stage

(the one which gives

x

B

) will appear on the graph at the solid equilibrium curve, not on

the dashed curve. The dashed curve is a “pseudo-equilibrium” which describes the two

phases when they don't have a chance to completely reach equilibrium.

(

=

Example 4.6: plutonium stabilization at Los Alamos National Laboratories

[4]

Problem:

Currently, the nitric acid used in plutonium stabilization operations at a particular

facility is evaporated to remove dissolved solids, assayed for radioactive content and

then sent via underground pipe to a low-level waste handling facility. The acid stream

is then neutralized with caustic to remove radioactivity and the resulting solids are

immobilized in cement as a TRU (trans-uranic waste). The filtrate is then sent for

Search WWH ::

Custom Search