Environmental Engineering Reference

In-Depth Information

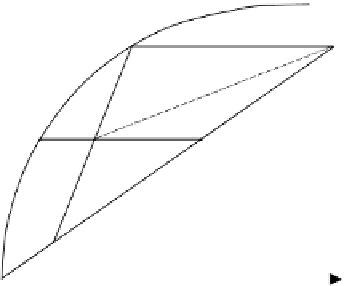

min. reflux

x

D

actual

L V

line

F

1

:sat'd vapor (

q

-line)

F

2

:subcooled liquid (

q

-line)

Figure 4.20

When

q

-lines cross.

What if the feed lines cross?

The

minimum reflux

ratio is still determined by the intersection of the operating line from

x

D

with the

q

-line which intersects the equilibrium line furthest up the column.

Stepping off stages

: starting from

x

D

, step off stages until you reach a

q

-line, then shift

to new operating line for optimum feed location. For Example 4.5 (Figure 4.20),

F

1

would

be introduced above

F

2

in the column.

Stage efficiencies

In the McCabe-Thiele analysis thus far, ideal equilibrium stages, or those with per-

fect efficiencies, have been assumed. An ideal stage is one in which thermodynamic

equilibrium between vapor and liquid phases entering each stage is reached before the

streams exit the stage. Non-ideal stages, or those with less than perfect efficiencies, do

not reach thermodynamic equilibrium. Two approaches exist for determining the num-

ber of real stages required to perform a separation as a function of the number of ideal

stages.

The first method uses an overall efficiency,

η

:

theoretical (equilibrium) stages

actual stages

η

=

×

100(%)

.

The number of real stages, then, is merely the number of ideal stages divided by the overall

efficiency. While this method is simple to use, the difficulty is in obtaining a value for the

overall efficiency of a column. In addition, the efficiency often varies from stage to stage,

making a single overall value somewhat meaningless. Often, if efficiencies of individual

stages can be estimated, they are averaged to give an overall value.

The second method used is the Murphree vapor efficiency:

y

n

−

y

n

−

1

E

MV

=

y

n

−

1

×

100(%)

,

y

n

−

Search WWH ::

Custom Search