Environmental Engineering Reference

In-Depth Information

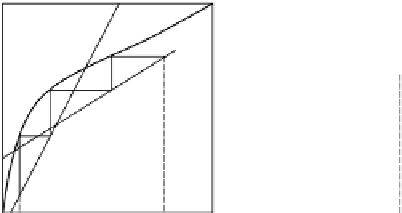

(a)

(b)

1

1

2

2

3

3

4

x

B

x

B

x

D

x

D

Figure 4.5

Feed stage location is (a) optimum, and (b) above optimum.

thermal condition are a good match to the column conditions on that stage (see Figure 4.5).

This point is the optimal feed stage; a separation will require the fewest total number of

stages when the optimum feed stage is used as the actual feed stage. If the feed is not at

the optimum stage location, the point at which you change operating lines is different. The

actual feed plate location is where the “steps” cross over from one operating line to

the other since the mass balance changes at that location. Under optimum conditions, one

always uses the operating line that is furthest from the equilibrium line.

The phase and temperature of the feed will affect the vapor and liquid flowrates in the

column. The mass and energy balances around the feed plate are:

+

+

=

+

F

V

L

L

V

Fh

F

+

VH

f

+

1

+

Lh

f

−

1

=

Lh

f

+

VH

f

,

(4.31)

where

h

F

is the enthalpy of the feed, and

f

is the location of the feed plate. Assuming

CMO means that the liquid an

d

vapor enthalpies don't vary much throughout the column.

Solving the mass balance for

V

−

V

and substituting into the energy balance gives:

L

−

L

H

−

h

F

=

h

=

q

=

quality

,

(4.32)

F

H

−

or, in words,

(vapor enthalpy on feed plate - feed enthalpy)

/

(vapor enthalpy on feed plate - liquid

enthalpy on feed plate)

the fraction of feed that is liquid.

Now remember that the feed plate is where the operating lines intersect each other.

Solving mass balances for the top and bottom sections of the column gives:

=

quality

=

=

+

yV

Lx

Dx

D

L

−

L

Fx

F

V

gives:

y

=−

V

x

+

V

.

(4.33)

yV

=

Lx

−

Bx

B

V

−

−

Since each term except

y

and

x

is constant, this is a straight line called the feed line.

Search WWH ::

Custom Search