Biomedical Engineering Reference

In-Depth Information

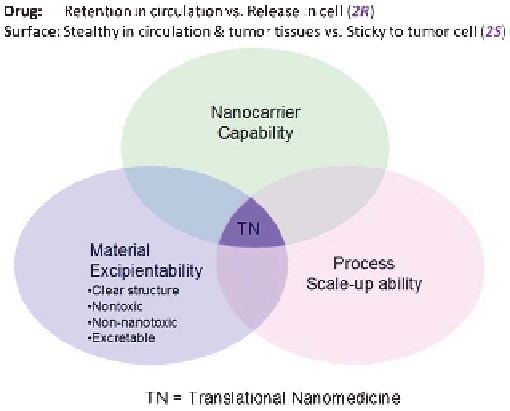

but harbors the most aggressive and resistant cells. On reaching the targeted cells

the nanocarrier must become ''sticky'' or ''cell binding'' to interact with the tumor

cell for efficient cellular uptake. A nanocarrier capable of simultaneously

satisfying such opposite 2R2S requirements at the right time and the right place,

that is, ''drug Retention in blood circulation vs. Release in tumor cells (2R)'' and

''surface Stealthy in blood circulation and tumor tissues vs. Sticky to tumor cells

(2S)'', will deliver the drug specifically to the tumor cells, giving rise to high

therapeutic efficacy and few side effects.

While the 2R2S capability of a nanocarrier may render the resulting

nanomedicine efficacious and potentially safe for clinical translation, two other

elements, namely the feasibility of the nanocarrier materials to be proved for use

as excipients (referred to as material excipientability) and the ability to establish

scaled-up production processes for good manufacturing practice (GMP) for the

nanocarrier and its formulation with the drug (nanomedicine) (referred to as

process scale-up ability) are also indispensible for the nanomedicine to be truly

translational from the benchtop to the bedside (Figure 3.2).

8

Most of our current

research is focused on using new material design and chemistry to improve the

2R2S capability; however, research aimed at translational applications should

comprehensively consider the other two elements at an early stage.

Herein, we briefly review the approaches addressing nanocarriers' 2R2S

capability and summarize the factors affecting material excipientability and

process

d

n

4

y

3

n

g

|

2

scale-up

ability,

aimed

at

promoting

the

developments

of

truly

translational nanomedicine for cancer drug delivery.

Figure 3.2

The three elements for translational nanomedicine: the nanocarrier

should have the 2R2S capability and its material should be suitable for

excipient use (referred to as material excipientability); the production of

the nanocarrier and its formulation with drug (nanomedicine) should be

able to scale up for good manufacture process (GMP) (scale-up ability).

Reprinted with permission from ref. 8. Copyright 2012 Elsevier.