Image Processing Reference

In-Depth Information

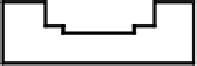

Note relief under image area

to avoid damage

Figure 4-19

Film guide cross-section.

ture a gate to hold the film steady as it passes through. This need not be anything more

complex than a film guide, but you must be careful to protect the imaging area of the film

to avoid scratching it, as you see in Figure 4-19.

Rather than use a slide scanner, consider carefully dismantling a video camera and

using the imaging system in that. Some high-end Telecine manufacturers such as CTM

Debrie Cinematography use Sony

HDCAM

components on an OEM basis to build their

systems.

4.12.2

Film Transport

Next you have to construct a framework to create a film path through the scanner. You will

need a couple of film pulleys. Most important for driving the film through, you will

require a suitable sprocket for the film gauge you are using. But there is no need to man-

ufacture a proper film gate with a claw mechanism. Dismantling a broken film projector

will yield the parts you need.

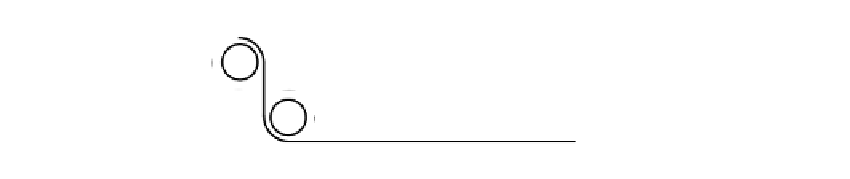

If you place a friction pulley on one side of the gate and a motorized sprocket to pull

it through the gate from the other side, this will provide sufficient control. The film must

remain taut. There are other tensioning devices available, and perhaps the cannibalized

projector will yield up a sprung double-pulley tensioner.

A projector synchronizes the movements of the film and the shutter by a complex

mechanism of gears and cams as discussed at the beginning of this chapter. That is

Tension

pulleys

Sprocket driven by

stepper motor

Slide scanner

Figure 4-20

Film path through scanner.

CTM Debrie Cinematography: http://www.ctmsolutions.com/

Search WWH ::

Custom Search