Environmental Engineering Reference

In-Depth Information

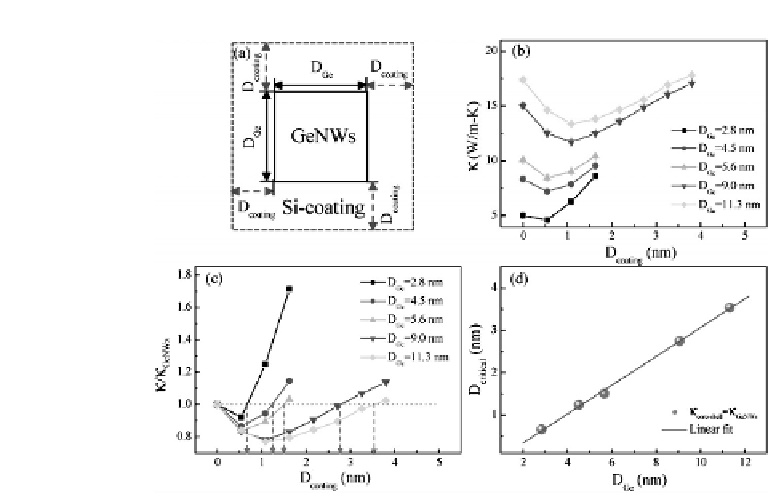

Figure 1.13

Coating configuration and thermal conductivity. (a) Cross-

section of GeNWs with Si-coating shell (dashed line). (b) Thermal

conductivity of GeNWs (

D

coating

=

0) and Ge/Si core-shell NWs (

D

coating

>

0)

for different

D

Ge

at room temperature. (c) Normalized thermal conductivity

versus coating thickness for different

D

Ge

. The dashed arrows point the

critical coating thickness when thermal conductivity of Ge/Si core-shell

NWs(

κ

GeNWs

).Thedashedlineisdrawn

to guide the eye. (d) The critical coating thickness

D

critical

versus cross-

sectional side length of GeNWs. The solid line draws the linear fitline.

κ

core

−

shell

)isequaltothatofGeNWs(

that for each GeNW, the coating of Si atomistic layers can reduce

the thermal conductivity. Further coating results in an increase of

thermal conductivity.

Increasingcoatingthicknesshastwooppositeeffectsonthermal

conductivity. On the one hand, the creation of core-shell structures

will induce the phonon resonance between the transverse and

longitudinal modes, thus offering a coherent mechanism to reduce

thermal conductivity. In Si-coated GeNW, atoms on the same cross-

section plane have different sound velocity in the longitudinal

direction. As a result, atoms near the interface are stretched, which

induces a strong coupling between the transverse and longitudinal

motions. Because of the spatial confinement on the cross-section