Geology Reference

In-Depth Information

=

due to the inherent eccentricity in the model

introduced in the fabrication process. This is not

analyzed further as the analytical predictions of

the experiments are quite close to the test results

across different displacement and acceleration

time-histories. Figure 7 shows the progress in

PSO convergence as the number of generations

in the optimization increased.

The mass of the base is measured to be 38 kg.

The stiffness of the linear springs attached co-

axially with the sliding isolator is measured using

servo-hydraulic testing machine. The stiffness of

each of the springs is found to be 2.162kN/m. A

nonlinear frictional damping

f

M

kg

a

62 76

.

0

0

0

64 20

.

0

0

0

59 40

.

Ns

m

2

C

=

×

10

a

5 23

.

−

2 23

.

0

−

2

.23

2 33

.

−

0 1

.

0

−

0 1

.

0 1

.

N

m

K

a

10

2

=

×

1 04

.

0 74

.

0

−

−

0

.

74

1 49

.

−

0 76

.

0

0 76

.

0 76

.

−

(

µ

is

considered for the isolator, where μ is the coef-

ficient of friction (Sahasrabuddhe and Nagara-

jaiah, 2005; Madden et al., 2002) and is given by

=

wz

b

w

(11)

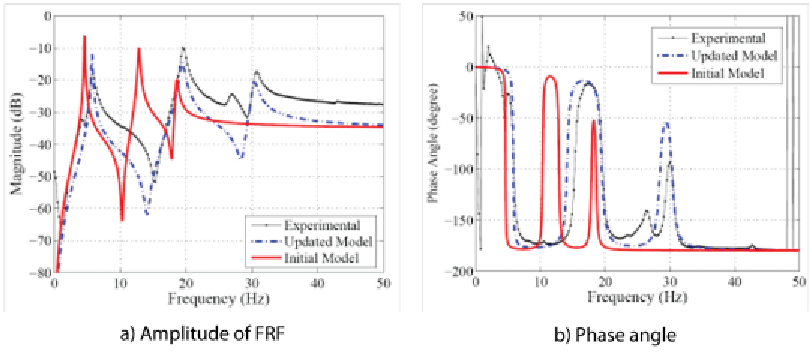

Figures 6a and 6b show the comparison of

amplitude and phase angles for experimental

and analytical models measured at third floor

respectively. Both the initial and updated analyti-

cal FRFs are presented to show the convergence

of updated model using PSO algorithm. Initial

model refers to system parameters prior to the

PSO runs. There is a small peak at 27.1Hz in the

experimental curve, which may be attributed to

some transverse motion present in the structure

x

−

λ

µ

=

µ

−

(

µ

−

µ

)

e

(12)

max

max

min

where

µ

ranges from

µ

max

at large velocities of

sliding to

µ

min

at very low velocities. λ is a con-

stant having units of time per unit length and

x

b

is the velocity across the isolator. The value to

Figure 6. FRF measured at third floor showing amplitude and phase angle on the initial guess, updated

model and the experimental obtained FRF

Search WWH ::

Custom Search