Geology Reference

In-Depth Information

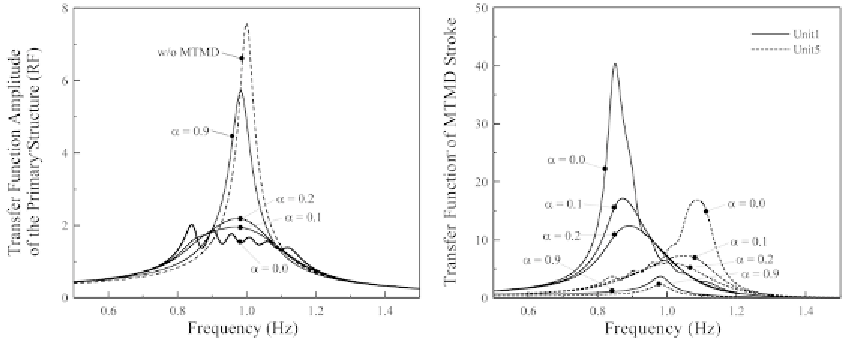

Figure 4. (a) Transfer function of roof displacement of a 3-story building-MTMD system with different

α

; (b) Transfer function of MTMD stroke with different

α

study, a real MTMD device was designed and

fabricated. Then, experiments were performed

on a 5m ×5m three-dimensional shake table. This

section describes the details and the results of the

study. It also provides a useful reference when a

real-life case is implemented.

building parameters; (3) Building-MTMD system

test: to evaluate the control effectiveness of

MTMD.

Two acceleration sensors and two displacement

sensors along the excitation direction at each floor

were deployed.

Test Program and Sensors Setup

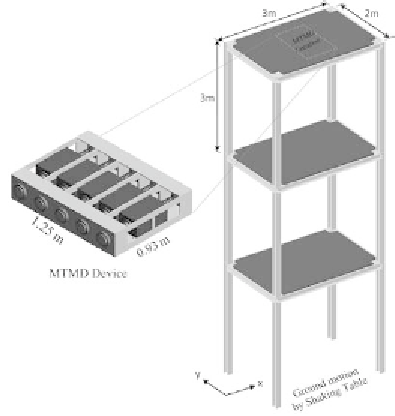

The experimental structure used in the experimen-

tal study was a large-scale three-story steel frame

as shown in Figure 5. This structure is regarded as

a benchmark building designed for the demonstra-

tion of research on structural control and health

monitoring in Taiwan. It was a uniform building

with total of 18 tons in weight and 9 m in height.

The dimension of the rectangular floor is 3 m × 2

m. Four columns of H-shape (H150×150×7×10)

section with the same section orientation are used

for support. The weak axis of the column section

is also the test direction.

The test program includes three major steps:

(1) Bare building test: to identify the dynamic

parameters of the building at the time and to es-

tablish the uncontrolled response for future com-

parisons; (2) MTMD design and fabrication: to

create the control device based on the identified

Figure 5. Configuration of 3-story building and

MTMD device

Search WWH ::

Custom Search