Graphics Reference

In-Depth Information

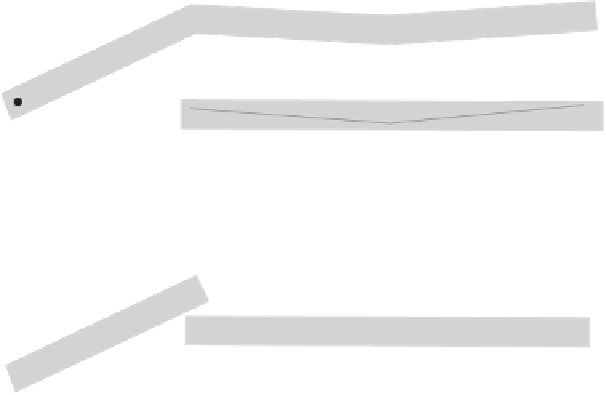

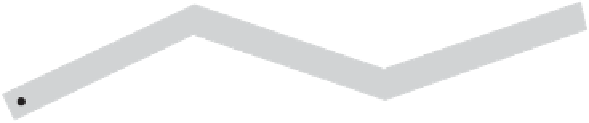

Figure 12.15

The upper illustration shows how an absolute merging tolerance smaller than

the plane thickness tolerance (in gray) avoids cracks from appearing between neighboring

faces. The lower illustration shows how a crack may appear when the merging tolerance

exceeds the plane thickness tolerance.

Worse, if vertices are unwelded and are allowed to move during merging cracks can

appear at the edges between neighboring faces unless the absolute merging tolerance

is kept smaller than the plane thickness tolerance. Figure 12.15 illustrates how a crack

may appear between a face and a merged face when the merging tolerance exceeds

the plane thickness tolerance. To avoid tolerance issues that would cause robustness

problems and to guarantee the reduction of faces due to merging, it is important

to use an absolute error measurement for merging geometry for use with collision

detection.

12.4.2

Testing Polygon Planarity

A polygon is defined by a set of vertices in the plane. Testing the polygon for planarity

then involves making sure all defining vertices lie in a plane. This can be done by

computing a plane equation for the supporting plane of the polygon and then testing

all vertices to make sure they are within some tolerance of the plane. The plane

equation for the supporting plane is obtained through computing a polygon normal

and selecting a reference point on the polygon.

This sounds simple enough, but there is a hidden subtlety: how to compute the

polygon normal

n

(

n

x

,

n

y

,

n

z

). A first approach to computing the polygon nor-

mal might involve computing the cross product of two coincident polygon edges.

However, this is not robust because the edges may be (near) collinear, causing the

=