Geology Reference

In-Depth Information

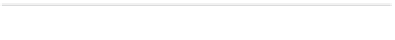

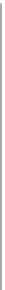

b)

a)

3

3

40%

shale

30%

2.8

2.8

30%

2.6

20%

2.6

(1)

2.4

2.4

10% porosity

20%

(3)

(4)

(6)

2.2

2.2

brine sand

brine sands

oil sands

shale 1

shale 2

shale model

oil sand model

brine sand model

10%

40%

clean sand

2

2

30%

35%

30%

20%

25%

1.8

1.8

10% porosity

Gas saturation

10%

100%

20%

(2)

15%

(5)

1.6

1.6

1.4

1.4

2000

4000 6000 8000 10000

Acoustic impedance (m/s.g/cc)

2000

4000 6000 8000 10000

Acoustic impedance (m/s.g/cc)

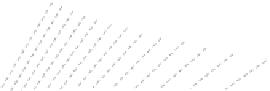

Figure 8.43

Rock physics template examples; a) a template crossplot showing the rock physics illustrating the vectors associated with certain

elastic changes relative to a reference brine sand: (1) increasing laminar shale, (2) increasing cementation, (3) increasing porosity, (4) decreasing

effective pressure, (5) increasing hydrocarbon saturation, (6) increasing dispersed shale content (modified after

degaard and Avseth,

2004

),

(b) an example of log data plotted from different lithofacies zones, together with rock physics model calibration trends.

ties. Log editing is therefore an important element of

the well tie process. Typical causes of bad hole condi-

tions are the presence of incompetent formations and

chemical interaction of mud filtrate and clays. In

many instances the caliper log is a key to recognising

bad hole. The density tool in particular has low toler-

ance of poor hole conditions.

Figure 8.44

shows an

example of zones of caving shales that have led to

errors in the density log. In this instance a corrected

log has been calculated by using sand and shale dens-

ities, mixed in the proportions indicated by the V

cl

log. Such a scheme is valid of course only where the

fluid fill is invariant and there is no depth dependency

in the density and sonic measurements.

In contrast to the density log, wireline sonic logs

are usually quite tolerant of poor borehole conditions.

However, in very bad hole the sonic signal, particu-

larly with conventional borehole sonic logs, can be

severely attenuated. This results in the amplitude of

the first arrival being too low to trigger the receiver,

which instead records higher amplitude later arrivals.

This

tolerant of bad hole than older designs (

Fig. 8.44

).

Sometimes sonic logs also show noise spikes where

the receivers are triggered by, for example, tool move-

ment. Log spikes deserve careful attention to distin-

guish noise from genuine responses for example

related to thin limestone stringers in a shale section.

Comparison with other logs such as density is usually

helpful. It is also worthwhile checking for potential

bad hole effects on the seismic drift curve generated

during log calibration (

Chapter 4

). The bad hole will

show up as zones in which sonic velocities are slower

than seismic velocities.

8.4.2 V

p

and V

s

from sonic waveform

analysis

Since the early 1990s shear wave logging has become

fairly routine. As discussed in

Section 8.3.2.2

,com-

pressional and shear logs are derived from an analysis

of sonic waveforms. In general, rig-based processing

products are not the best quality. Final logs are

generated from detailed analysis in a dedicated pro-

cessing centre. In projects where there are a number

of wells with variable age shear logs, interpreted by

different contractors, it is unlikely that the interpret-

ations will be consistent. In such a situation it is well

worth considering re-processing all the wells to obtain

a consistent dataset prior to the start of the project.

can lead to sonic transit times

that are too high (i.e. velocities too low) (

Fig. 8.45

).

In

Fig. 8.45

the effect of cycle skips in bad hole has

been corrected by defining a relationship between

deep conductivity (i.e the reciprocal of the deep resist-

ivity log) and sonic slowness (Burch

2002

). Modern

dipole and other advanced sonic tools are more

'

cycleskipping

'

183