Biomedical Engineering Reference

In-Depth Information

1 V just on the lead conductor. The resistance of defibrillation

leads is much less because of the usage of conductors with a

larger diameter; the maximum is about 2 Ω.

7.1.4

Construction of Lead Connectors

In the early stages of the cardiac pacing, the incompatibility of

lead connectors and connector headers on a device was a tech-

nical problem. In those days, the necessary technical stan-

dards were neither created nor applied yet. Development went

through various socket joints and bayonet systems, to 5- to

6-mm unipolar or bifurcate bipolar connectors, and finally to

3.2-mm bipolar connectors. These connectors already con-

tained two double-tandem contacts for every pacing electrode.

Lack of unity also dominated in the area of seal plugs and

placement of liners. Some manufacturers left them at the lead

connector, others in the port of the device's connector header.

In this situation, manufacturers made a provisional agreement

dealing with a voluntary standard for lead connectors and seal

plugs and used a 3.2 mm connector (VS-1). Lasting problems

with the acceptability of this standard finally were solved by

the acceptance of the international technical standard for a

bipolar connector of the pacing lead, designated as IS-1

(Fig.

7.7

). It currently deals with the international standard

ISO 5841-3:2000 Implants for Surgery - Cardiac Pacemakers

- Part 3: Low-Profile Connectors (IS-1) for Implantable

Pacemakers

. The connector is tubular to enable introduction

of the stylet or guide wire. The standard currently is used for

cardiac pacing leads. Despite this standard, when heart resyn-

chronization therapy was put into wider practice, a specific

connector - type LV-1 - was designed for the left ventricular

lead in which the seal plugs are placed in a port on the device

header instead of on the lead connector. This enabled the cath-

eter used to access the coronary sinus to be pulled over the

lead connector in the case of dislocation of the left ventricular

lead that was previously applied. However, when the

proficiency in insertion of the left ventricular leads increased,

the usage of this connector was terminated.

The international standard for the connector of one elec-

trode of the DF-1 defibrillation lead is

ISO 11318:2002

Cardiac Defibrillators - Connector Assembly DF-1 for

Implantable Defibrillators - Dimensions and Test

Requirements

. According to whether it uses one or two shock

electrodes, the defibrillation lead might be equipped with

two (IS-1 + DF-1) or three (IS-1 + 2 × DF-1) connectors. The

DF-1 connector is unipolar only and it is not tubular.

In connection with the miniaturization of the dimensions

of implantable cardioverter-defibrillators and cardiac resyn-

chronization therapy for defibrillators and with the reduction

of the mechanical connection of leads to the device connec-

tor header, an effort was made to deal with the elimination of

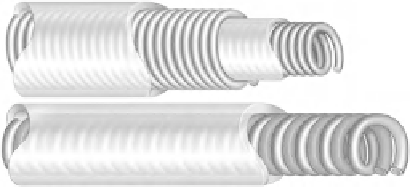

Fig. 7.5

Coaxial and co-radial lead conductor designs

Fig. 7.6

Cross section of a de fi brillation lead

for defibrillation, according to whether it deals with a lead

with one or two defibrillation shock electrodes. Regarding

their construction, defibrillation leads are divided into inte-

grated bipolar leads, which include electrically connected

electrodes (the proximal pacing electrode and the distal

shock electrode), and separated bipolar leads, in which the

electrodes are separated. The conductors are insulated by, for

example, tetrafluoroethylene in isolated channels inside the

body of the lead, which is made of silicone rubber. The sec-

ond layer of insulation covers the lead body and ensures

additional insulation and a unique diameter (see Fig.

7.6

).

The most liable place for mechanical damage of the

implanted lead is usually near the crossing of the subclavian

vein and the first rib. Fixation that is too strong at the point

where the lead enters into the vein might damage the insula-

tion, especially if a suture sleeve (lead protector) is not used

for the suturing.

The lead conductor, together with the pacing electrodes,

predominantly designate the electrical properties of the lead.

The total electrical resistance of the conductor between the

connectors and pacing electrodes might range from about

30 to 150 Ω. It depends on the lead length. This value is not

negligible, and it creates a considerable part of the impedance

value within the pacing circuit. With pacing by a current of,

for example, about 7 mA, there is a decrease in voltage up to