Biomedical Engineering Reference

In-Depth Information

1.9.1 Flow Measurement

Accurate measurement of flow rate of liquids and gases is an essential requirement

for maintaining the quality of industrial processes. In fact, most of the industrial

control loops control the flow rates of incoming liquids or gases in order to achieve

the control objective. As a result, accurate measurement of flow rate is very

important. Various techniques are available for measuring flow. Each technique

has its advantages and disadvantages, and selecting a proper technique depends on

its specific applications [

5

].

Needless to say that there could be diverse requirements of flow measurement,

depending upon the situation. It could be volumetric or mass flow rate, the medium

could be gas or liquid, the measurement could be intrusive or nonintrusive, and so

on. As a result, different types of flow measuring techniques are used in industries.

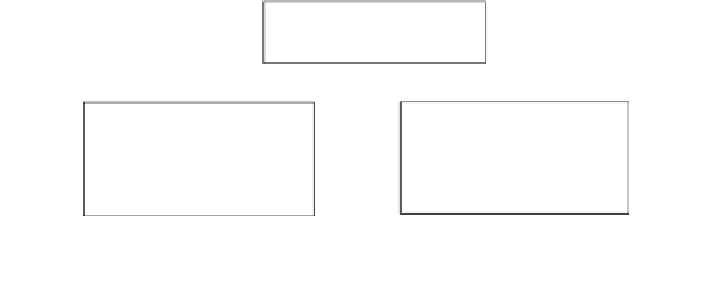

The common types of flow meters that find industrial applications can be listed as

below in Fig.

1.6

.

1.9.2 Pressure Measurement

Measurement of pressure inside a pipeline or a container in an industrial envi-

ronment is a challenging task, keeping in mind that pressure may be very high, or

very low (vacuum); the medium may be liquid, or gaseous. Pressure is a force

generated inside a sealed volume by the atoms and molecules either pressing out

(positive pressure) or pulling in (negative pressure).

Different methods are available for measurement of pressure and force. Elastic

elements, namely diaphragms and bourdon tubes are mainly used for pressure

measurement. On the other hand, strain gages are commonly used for measure-

ment of force. These elastic elements change their shape with applied pressure and

the change of shape can be measured using suitable deflection transducers.

Flow Measurement

Techniques

Integral Properties of flows

(Mass, Volume etc.)

1. Coriolis Technique

2. Rotameter

3. Orifice meter

4. Flow Nozzle.

Local flow parameters

(Local velocity etc.)

1. Hot wire anemometer

2. Laser Doppler anemometer

3. Particle image velocimetry

4. Ultrasonic technique

Fig. 1.6 Types of flow meters. a Obstruction type (differential pressure or variable area).

b Inferential (turbine type). c Electromagnetic. d Positive displacement (integrating). e Fluid

dynamic (vortex shedding). f Anemometer. g Ultrasonic. h Mass flow meter (Coriolis)

Search WWH ::

Custom Search