Biomedical Engineering Reference

In-Depth Information

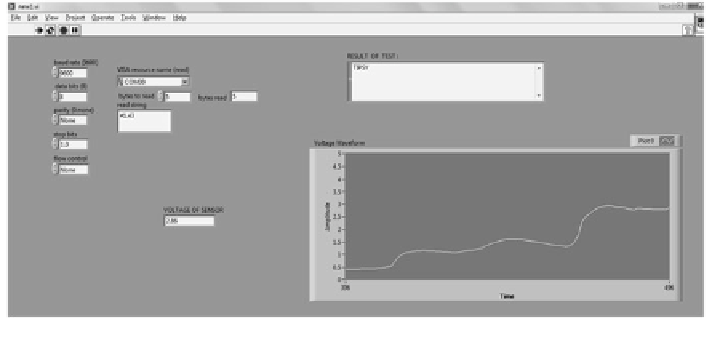

Fig. 8.17

Front panel of Lab VIEW for result display

8.2.4 Conclusion

The E-nose design has a wide area of application. But as the sensors used take a

good amount of time and preheating (i.e., TGS Sensor required preheating period

before testing for more than 7 days) to give stable output. Also, it was quite

difficult to calibrate the sensor (i.e., MQ3 sensor sensitivity is different to various

kinds and various concentrations of gases, so sensitivity adjustment is necessary).

Finally, after repeated testing of the sensor, with fine calibration of the system,

reliable and accurate results can be obtained.

References

1. O. Özgür, B. Karlık, An Overview of Metal Oxide Semiconducting Sensors in Electronic

Nose Applications, International Burch University, Department of Information Technology

2. A.D. Wilson et al., Applications and advances in electronic-nose technologies. Sensors 9,

5099-5148 (2009). doi:

10.3390/s90705099

3. P. Russell, Sensory analysis. Milk Ind. Int. 97, 11-12 (1995)

4. D. Sivalingam, J.B. Balaguru Rayappan, Development of E-nose prototype for raw milk

quality discrimination. Milchwissenschaft 67(4), 381 (2012)

5. S. Ampuero et al., The electronic nose applied to dairy products: A review. Sens. Actuators B

94, 1-12 (2003)

6. K.M. Horváth, Z.S. Seregely, I. Dalmadi, E. Andrassy, J. Farkas, Estimation of

bacteriological spoilage of pork cutlets by electronic nose. Acta Microbiol. Immunol.

Hung. 54(2), 179-194 (2007)

7. M. Ghasemi-Varnamkhasti et al., Meat quality assessment by electronic nose (machine

olfaction technology). Sensors 9, 6058-6083 (2009). doi:

10.3390/s90806058

8. H. GholamHosseini, D. Luo, H. Liu, G. Xu, Intelligent processing of E-nose information for

fish

freshness

assessment.

3rd

international

conference

on

''intelligent

sensors,

sensor

networks and information'', 2007. ISSNIP 2007

Search WWH ::

Custom Search