Biomedical Engineering Reference

In-Depth Information

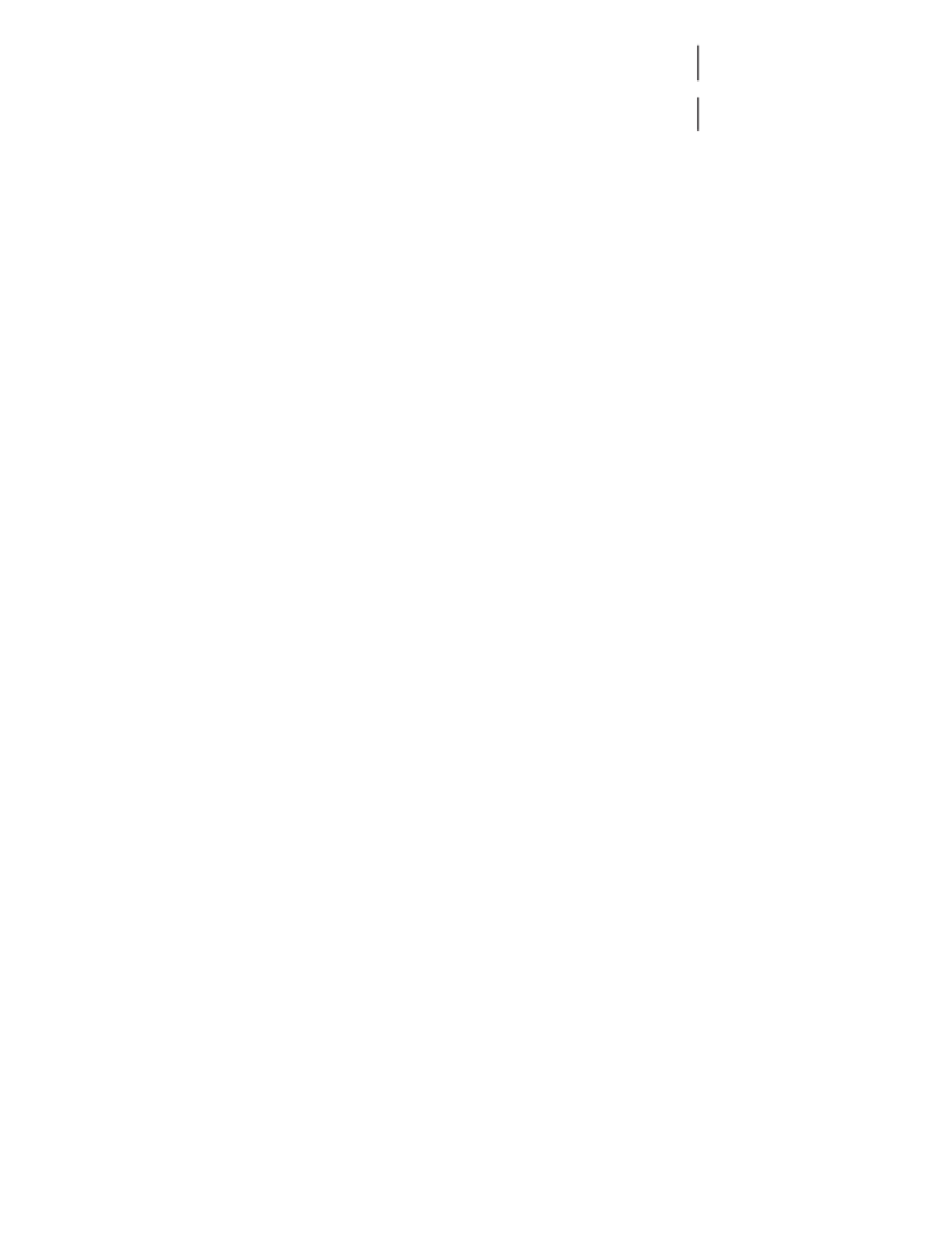

ROCOR

1

H

2

C

OCOR

1

H

2

C

OH

+

Catalyst

OCOR

2

HC

+

ROH

HC

OH

ROCOR

2

+

+

OCOR

3

H

2

C

ROCOR

3

H

2

C

OH

Triglyceride

Alcohol

Mixture of

Alkyl Esters

Glycerol

Triacylglycerides

+

Alcohol

Diacylglycerides

+

FAAE

+

Alcohol

Monoacylglycerides

+

FAAE

Diacylglycerides

Monoacylglycerides

+

Alcohol

Glycerol

+

FAAE

Figure 14.5

Preparation of fatty acid alkyl esters by transesterification.

Thus, a combination of different enzymes is found to be more efficient in catalyzing FAAE

production in comparison to the single lipase system.

Table 14.4 shows a list of CALB lipase-catalyzed transesterification reactions using metha-

nol as the acyl acceptor. Although methanol is the cheapest source of acyl acceptor, it has a

harmful effect on biocatalysts. In countries where ethanol production from renewable feedstocks

is economically feasible, ethanol is the more preferable acyl acceptor (Kojima

et al

., 2004 ).

Stoichiometrically, a 3:1 molar ratio of alcohol to oil is needed for complete transesteri-

fication reaction. Nevertheless, the solubility of short chain alcohols, namely methanol and

ethanol, in vegetable oil is only 1/2 and 2/3 of the stoichiometric amount, respectively. The

insoluble alcohols form either emulsion droplets under continuous stirring or a heterogeneous

alcohol phase in equilibrium conditions, with the oil phase leading to inactivation of

enzymes and, subsequently, lower conversion rate (Shimada

et al

., 1999 ). To minimize the

effect of lipase inactivation, Shimada and co-workers (1999) performed a stepwise addition

of methanol. This procedure was found to be effective with close to complete conversion of

FAAE (98.4%). The use of organic solvents to improve substrate miscibility is deemed

undesirable considering the cost of recovery and also increasing environmental concerns.

The cost concern also applies to the use of ionic liquids despite them being green solvents

(Ha

et al

., 2007). On the other hand, recycling or addition of FAAE as the co-solvent seems

a promising possibility for keeping the reaction media homogeneous and, thus, increasing

mass transfer and reaction rates (Fjerbæk

et al

., 2009 ).

The quality of feedstock plays an important role in enzymatic processing. Alternative oil

sources, such as waste frying oils, inedible vegetable oils and waste oils from processing

industries, which are cheaper than edible vegetable oils, are potential feedstocks for FAAE

production. Biocatalysts are preferable for such type of feedstocks. Lipases can simultane-

ously esterify and transesterify FFA and oils. Thus, it can convert low quality oils, such as

high FFA oils and restaurant greases, and inedible oils, such as Jatropha and castor oil, into

FAAE at reasonably good yields. Basic catalysts have the tendency of forming soap with

such feedstocks. Although acid catalysts, for example hydrochloric or sulfuric acid, do not

have such drawbacks, the reaction rates are much slower (Robles-Medina

et al

., 2009 ).

Enzymatic FAAE production does have its constraints. The major constraint to enzymatic

production of FAAE is substrate immiscibility. Both the substrates, oil and alcohol, have

Search WWH ::

Custom Search