Biomedical Engineering Reference

In-Depth Information

Fiber output

Scutching

(fiber top)

Scutching

(fiber bottom)

Stalk breaking

Bale opening

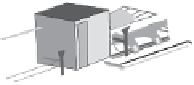

Figure 12.5

Flax scutching line. (Courtesy of Van Dommele Engineering.)

Figure 12.5, the scutching is performed by a turbine with its axis along the fiber moving

direction. There are two scutching steps. In the first step, two turbines are used for scutching

bast fiber bottoms. The second scutching step uses two other turbines to beat on bast fiber

tops. The removed trash particles and short fiber are transported to a collecting unit through

funnels and a pneumatic transportation system. Some scutching lines use a cylinder to

perform scutching process. Bast fiber layer, with a fiber-laying orientation perpendicular to

its moving direction, is moved by feeding rolls into a scutching area, where the bast fiber is

beaten by the spring steel blades mounted on the surface of a rotating cylinder to scrape off

woody core particles and short fiber (called tow fiber). In this case, the cylinder axis is parallel

to the fiber-laying orientation. Two scutching units are needed, one for rough scutching and

another for fine scutching. Additionally, this cylinder scutching is often followed by a

separating unit. This unit is composed of shaking screens that shake up fiber bundles and let

loose shives and short fiber fall into an vacuum chamber underneath the shaking screens.

Thus, clean bast fiber with shorter stalk length is produced. This line fiber product can be

packed and stored directly, or can be cut and baled by an automatic hydraulic baling press.

Another technology is a decorticating line, which produces short staple bast fiber, woody

core, and seed. Figure 12.6 exhibits the major components that constitute this bale-to-bale

fiber processing line (Temafa GmbH, 2005). In comparison with the above scutching line,

these critical components include bale opening, stalk breaking, fiber breaking and separating,

fiber opening and cleaning and bale press. After a fiber stalk bale is delivered to the feeding

point of this line, the bale is opened and fiber stalk is spread out on a moving belt to form a

continuous layer using an opener and divider. Because the decorticating line is designed for

short staple fiber production, fiber stalk laid on the moving belt does not necessarily keep

parallel. The fiber stalk breaking unit uses a large-size cylinder surfaced with scattered

beaters to crush the woody core inside the fiber. Two stalk breaking units can be arranged to

achieve a better efficiency of woody core breaking. The crushed fiber stalk is fed through

retaining rollers to a fiber breaking and separating unit to break fiber bundles and small size

shives. This is performed by a set of crushing rollers. To separate the crushed shives from

fiber bundles, horizontal or angled shaking screens are used for removing short fiber and

shives during the transportation of fiber bundles.

Search WWH ::

Custom Search