Biomedical Engineering Reference

In-Depth Information

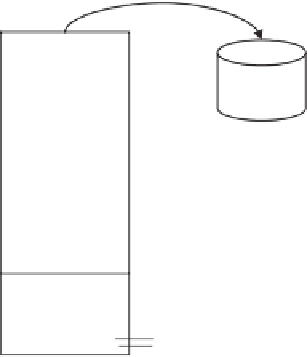

Foam

breaker

Foam

(containing protein)

Separated protein

Feed

(Liquid containing

protein)

Bottoms

Inert gas

Figure 3.4

Schematic process for foam fractionation.

are created as a result of the passage of gas through a liquid medium. Proteins with greater

surface activity orientate themselves and are capable of being adsorbed at the gas-liquid

interface created during bubble formation. A schematic of a typical foam fractionation set

up is presented in Figure 3.4. Bubbles leaving the surface of the feed solution carry both

adsorbed compounds and bulk liquid into the foam; as the interstitial liquid drains back

along the lamella of the bubbles, non-adsorbed solutes are returned to the retentate leaving

an enriched foam (Wang

et al

., 2009). The remaining liquid contained in the gas phase

is, thus, selectively enriched with protein having greater surface activity compared to the

proteins retained in solution.

Foam fractionation is a relatively inexpensive technique for protein separation. Most

studies in the literature are, however, experimental and very few report on industrial

applications. Among other applications, foam fractionation has been used to separate wheat

flour proteins, ovalbumin, lysozyme, egg albumin, milk proteins (e.g., beta-casein, bovine

lactoferrin, bovine serum albumin, alpha-lactalbumin, and beta-lactoglobulin) and potato

protein from potato juice waste water after starch extraction (Weijenberg

et al

., 1978 ; Keller

et al

., 1997 ; Hossain and Fenton, 1998 ; Brown

et al

., 1999 ; Wang and Liu, 2003 ; Wang

et al

., 2009 ).

Parameters influencing efficiency of protein separation include bubble size distribution,

bubble rupture and coalescence, fluid drainage and rate of bubble formation. Separation

ratio (SR) defines the ratio between the protein concentration in the foam and that in the

starting solution (feed). Separation efficiency (SE), on the other hand, is the product of the

flow rate of the foam phase and protein concentration in the foam divided by the product of

the flow rate of the liquid effluent and protein concentration of the effluent. Separation ratio

is affected by the feed protein concentration (FPC), feed flow rate (FFR), gas velocity (GV)

and the height of sampling (HS). For a given superficial GV, SR decreases with an increase

of FPC (Wang and Liu, 2003). Additionally, the averaged protein concentration in the foam

decreases with increasing GV; SR decreases with increasing FFR. Increasing the gas to feed

flow rate ratio (G/F) decreases SR up to a critical G/F beyond which a plateau is reached.

Search WWH ::

Custom Search