Biomedical Engineering Reference

In-Depth Information

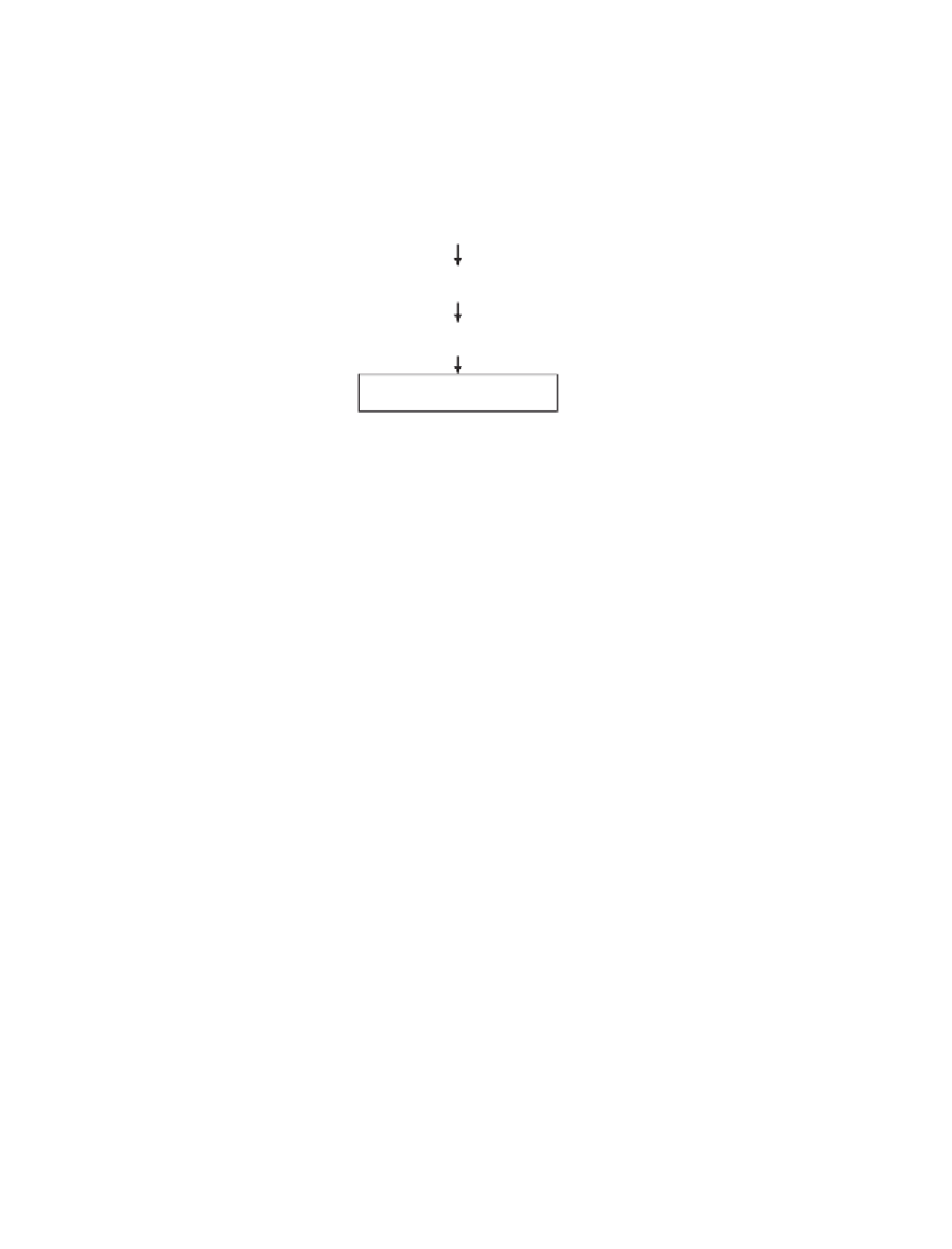

Starting material

Material preparation

(e.g., cleaning, dehulling, grinding, communition, etc.)

Fat extraction

(if necessary)

Protein extraction

Centrifugation / filtration

Protein precipitation

Centrifugation / filtration

Protein purification

(if needed)

Protein renaturation

Drying

Protein concentrate / isolate

Figure 3.3

General schematic showing some key unit operations for the wet processing of proteins.

operations used for the wet processing of proteins are presented in Figure 3.3. Deviations to

these operations occur depending on the starting material and the desired end product. The

material preparation step for wet processing will, therefore, vary depending on the source

material.

3.3.1 Dryprocessing

3.3.1.1

Airclassification

Air classification is a milling technique that allows the fractionation of plant grains/seeds

into high starch and high protein flours. The milling process yields flours having particles of

two discrete sizes and densities. Air classification exploits this phenomenon to separate the

light fine fraction (protein) from the heavy coarse fraction (starch).

During air classification, whole or de-hulled seed is ground into very fine flour, and the

flour is subsequently classified in a spiral air stream to separate the starch from the protein.

Repeating the process a few times improves separation efficiency, as protein bodies can

still adhere to the surface of starch granules after the initial run. Agglomerates present in

this initial starch fraction consist of starch granules embedded in a protein matrix, but by

repeated pin milling and air classification, further purification can be obtained (Gueguen

et al

., 1984 ).

Search WWH ::

Custom Search