Biomedical Engineering Reference

In-Depth Information

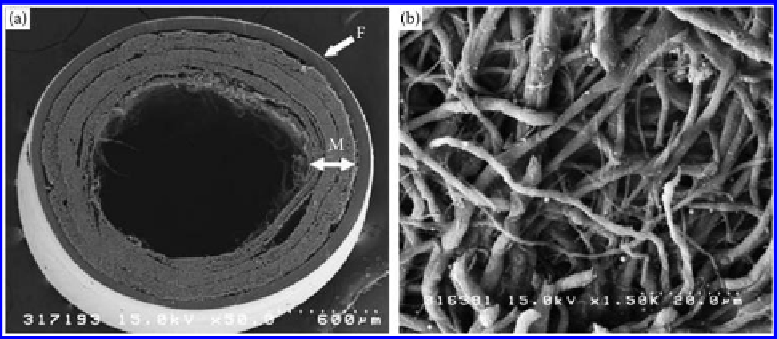

Figure 9.37

(a) SEM micrographs of the bilayered chitosan tube. F, chitosan film; and M, electrospun nano/microfiber mesh.

(b) Enlargement of the electrospun nano/microfiber mesh. The nano/microfiber structure comprises randomly

oriented fibers. 3D pores formed among fibers are interconnected and distributed throughout the structure.

(From Wang, W. et al. 2008.

J Biomed Mater Res

84A: 557-566; Wang, W. et al. 2008.

J Biomed Mater Res

85A: 919-

928. With permission.)

outer layer of chitosan film and an inner layer of electrospun chitosan nonwoven have

been developed (

cf.

Figure 9.37) [194,195]. 3D pores formed between fibers were intercon-

nected and distributed throughout the structure. The porosity improves the exchange of

nutrients and metabolic waste between the scaffold and surrounding tissue. The compres-

sive strength of the bilayered chitosan conduits was significantly greater than that of the

chitosan fiber mesh conduits. The bilayer chitosan-based conduits can improve nerve

regeneration, and the efficiency of nerve regeneration into bilayer chitosan tubes with

immobilized CGGGGGGYIGSR peptide was similar to that of the isograft. Axonal regen-

eration parallel to aligned Schwann cells is reported in injured peripheral and central

nerves

in vivo

. Inducing Schwann cell alignment resulting in oriented axonal growth

while preventing neuroma formation in the peripheral nerve injury is very important

during the process of nerve regeneration. Itoh and coworkers [196] constructed bilayered

chitosan fiber conduits with an inner layer of oriented nanofibers and an outer layer of

randomized nanofibers. Schwann cells aligned in the same direction as a result of secure

adhesion to the oriented fibers, but had no specific orientation on randomized nanofibers.

The oriented chitosan nanofiber mesh tube may be a promising substitute for an autoge-

nous nerve graft.

The degradation of chitosan used to date in nerve regeneration is very slow and poorly

controlled. As a source material of chitosan, chitin has attracted much less research inter-

est mainly because of the difficulty in processing it into the desired shape and also because

of uncertainty of its biological properties, especially nerve cell affinity. Gu and coworkers

[197] developed a two-step procedure to prepare tailored chitin products indirectly starting

from chitosan counterparts. This “chitin” and chitosan materials were equally biocompatible

to cultured Schwann cells. The degradation rate of “chitin” is higher than that of chitosan.

Moreover, the shapes of implanted chitin conduits in nerve defects were completely

changed, turning into a number of opalescent pieces, whereas the shapes of the chitosan

conduits still showed no conspicuous alterations and there was little inflammation at

the implantation spots (

cf.

Figure 9.38)

.

Carboxymethyl chitosan, a dissolvable chitosan

derivative, also possesses many desirable physiochemical and biological features that are

Search WWH ::

Custom Search