Biomedical Engineering Reference

In-Depth Information

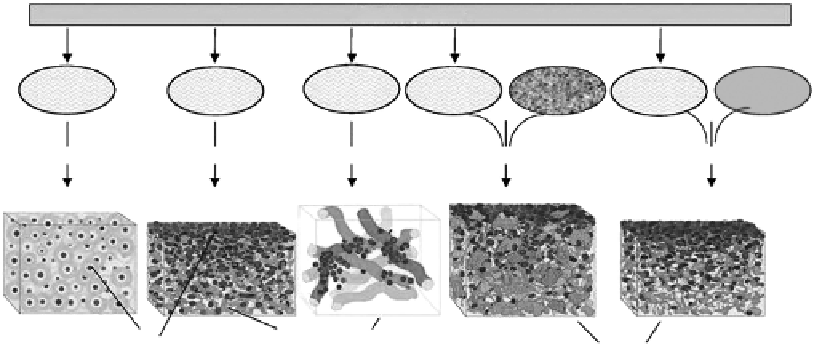

Chitosan

Calcium-

phosphate.

Chitosan sol.

Chitosan sol.

Chitosan sol.

Chitosan sol.

Chitosan sol.

Gelatin

(

In-situ

) gelling

Lyophilization

We t spinning

Lyophilization

Lyophilization

Porous matrices

Cells

Composite matrices

Figure 9.1

Illustration of selected examples of chitosan processing for use in tissue engineering. (From Martino, A. D. et al.

Biomaterials

26: 5983-5990. With permission.)

and the porosity of chitosan scaffolds increased accordingly with decreasing chitosan

concentration. The reason is obvious, since the actual volume fraction occupied by the

material itself decreased as the chitosan concentration decreased [4]. Mean pore diameters

could be controlled within the range 1-300 μm by varying the freezing conditions. The

pore size depended on the size of ice crystals. At a lower freezing temperature, the number

of nuclei of ice crystallization initially formed is more than that at a higher freezing tem-

perature, which results in the formation of ice crystals of small size. Thus, the pore sizes

become smaller and pore walls thinner, while interconnectivity increases with declining

prefreezing temperature [5]. The pores of 88% and 95% degree of deacetylation (DD) chito-

san scaffolds are not obviously different with variation of the pore size, whereas the pores

of 70% DD scaffolds are larger [6].

In fact, these traditional chitosan-based porous scaffolds cannot achieve the requirements

of complicated tissue. Bilayer chitosan-based scaffolds were prepared by quickly freezing

on a stainless-steel plate, which gives direct contact with the cooling plate while being open

to the air on top, as shown in Figure 9.2 [7,8]. There is a temperature gradient between the

stainless-steel heat sink and the air heat sink. So a corresponding temperature gradient

forms within the scaffold precursor. The pore size of the bottom layer contacting the refrig-

erating shutter directly is smaller than that of the air contacting top layer (

cf.

Figure 9.3).

However, the microstructure of a chitosan-based scaffold prepared via freeze-drying

Air

Chitosan solution

Stainless steel plate

Figure 9.2

Formation of the bilayer chitosan scaffold model. (From Liu, H. F. et al. 2004.

J Biomater Sci Polymer Edn

15: 25-40.

With permission.)

Search WWH ::

Custom Search