Biomedical Engineering Reference

In-Depth Information

In this method, chitosan was dissolved in acetic acid solution to form a thick jelly mass

that was cross-linked by adding glutaraldehyde. The nonsticky cross-linked mass was

passed through a sieve with a suitable mesh size to obtain microparticles. NaOH solution

was used to remove unreacted excess glutaraldehyde. This method is devoid of tedious

procedures, and can be scaled up easily. The average size of drug-loaded microparticles

was in the range of 543-698 μm.

6.4.3 Membranes and Films

Hydrogel membranes or films have been widely used as drug carriers in the case of trans-

dermal drug delivery. Several key properties enable the hydrogel membranes or films to

be one of the ideal carriers for skin drug delivery, including flexibility and elasticity suffi-

cient to follow the movements of the skin, enough strength to resist abrasion, high water

vapor transmission rate, effective drug permeability, bioadhesion, and a good feel for the

patient [95]. Chitosan has film-forming ability, bioadhesivity, antimicrobial activity, wound

healing, and absorption-enhancing properties [96]. By using a proper fabrication tech-

nique, chitosan-based membranes or films with good mechanical and physical properties

can be prepared, acting as an eligible drug carrier.

One of the most common techniques for the preparation of chitosan membranes or films

is the solvent cast-evaporation method [97]. In a typical procedure, a clear solution of chito-

san was obtained by dissolving chitosan in an aqueous solution of acetic acid. The biopoly-

mer solution was cast onto clean glass Petri dishes, and the solvent was slowly evaporated

at room temperature or in an air oven at 50-60°C. The dry chitosan films were easily sepa-

rated from the glass surfaces which were then immersed into a cross-linking solution con-

taining glutaraldehyde. PEC membranes of chitosan were also prepared by mixing with

another polyanion and then casting on glass dishes to evaporate the solvent [95,98].

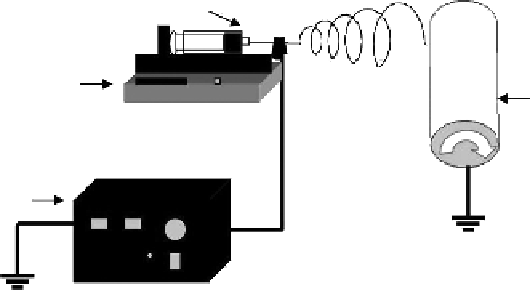

Recently, electrospinning techniques have increasingly been used to prepare polymer

membranes with continuous nanometer-scaled fibers as novel drug vehicles [99-101]. This

technique involves the use of an electrospinning setup (as shown in Figure 6.13). Chitosan

is dissolved in an appropriate solvent to obtain a transparent solution. Then the solution is

added into a syringe attached with a clinic-shaped metal capillary. The feeding rate of the

solution was set via a syringe pump. When a high voltage is applied between the metal

capillary tip and a grounded collector, the liquid droplets are charged and are subsequently

Polymer solution

Syringe pump

Grounder

rotating drum

High voltage

power supply

Figure 6.13

Schematic diagram of the electrospun scaffold experimental setup.

Search WWH ::

Custom Search