Biomedical Engineering Reference

In-Depth Information

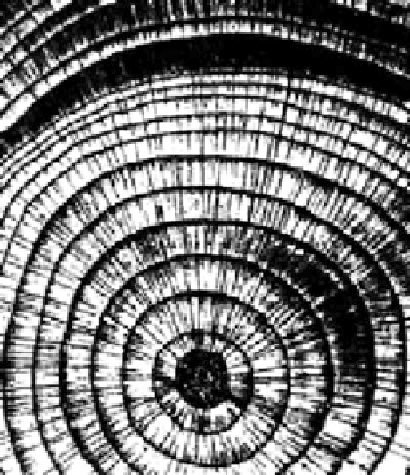

Fig. 4.5

The cylindrical

layers associated with each

year's growth in wood; note

curvilinear orthotropic

symmetry

obtain a laminar composite such as that shown in the remaining panels of Fig.

4.4

.

It is possible to form cylinders and spheres from these laminae. Wood is a natural

composite composed of approximately cylindrical layers associated with each

year's growth. These growth rings are illustrated in Fig.

4.5

. In Fig.

4.6

there is

an illustration of the microstructure of a biological material, a three-dimensional

view of a nasturtium petiole. In each of these illustrations, it is possible to see how

the microstructure of the material will give the material a distinctive anisotropy.

Such materials are often called natural composite materials. Bone tissue, bamboo,

teeth, and muscles are other examples. These materials evolve their particular

microstructures in response to the environmental forces of natural selection.

The method of formation of geological materials generally provides them with a

definitive layering that makes them anisotropic. The layered structure is easily seen

to be analogous to a layered composite. The deposition of layers is influenced by

particle size, because different size particles fall through liquids at different rates.

Gravity is the force that gives geological sediments their initial layering. Plate

tectonic forces then force these layers in directions other than that in which they

were formed, that is why the layers are often viewed in situations where the normal

to the plane of the layer is not the direction of gravity.

Macrocomposite man-made materials such as reinforced concrete beams, skis,

and helicopter blades are easily seen to be elastically anisotropic. These materials

are designed to be anisotropic. In the process of deformation or in the

manufacturing process, anisotropy is induced in a material. Anisotropy is also

induced in geological and biological materials by deformation. The manufacture

of steel by extrusion or rolling induces anisotropy in the steel product as illustrated

in Fig.

4.7

. Also illustrated, in Fig.

4.8

, is the anisotropy induced by deformation.

Search WWH ::

Custom Search