Biomedical Engineering Reference

In-Depth Information

Penza

. [291] demonstrated an advanced SAW sensor

configured as Love wave using a ZnO guiding layer on 36° Y-cut

X-propagation

et al

piezoelectric substrate, designed and

fabricated for toxic gas sensing applications, at room temperature.

SWCNT-based nanocomposite coatings were deposited using the

Langmuir-Blodgett technique. The sensor was tested toward H

LiTaO

3

,

2

NH

gases, in the range of 0.030-1%, 30-1000 ppm, 1-10 ppm,

respectively. The output signal was the phase of the SAW device,

which was monitored using a network analyzer. The developed sensor

exhibited high sensitivity, good repeatability, and low detection limit

at sub-ppm levels, at room temperature. The experimental results

obtained were compared to a theoretical model and the gas sensing

mechanisms were discussed with the acoustoelectric effect that

appeared to be dominant in the SAW response.

, NO

3

2

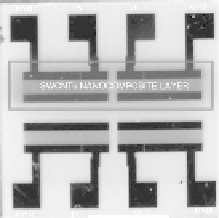

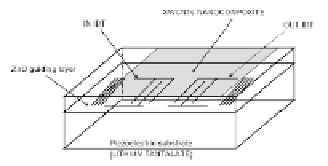

Figure 9.38

(

) Photograph of the dual 69 MHz two-port resonator

integrated onto lithium tantalate substrate. (

Left

Right

) Scheme of

the ZnO/LiTaO

layered SAW two-port resonator gas sensor

with CNT-based nanocomposite LB film as gas-sensitive

layer. This figure is reprinted and adapted with permission

from Elsevier [291].

3

These SAW devices (see Fig. 9.38) were two-port resonators

fabricated on a 0.5 mm thick 36° YX LiTaO

substrate. The IDTs

consisted of 38 finger pairs in each port. The 160 acoustic reflectors

with a periodicity (wavelength) of 40

3

m at each end of the device

were used to create a resonant cavity. The metallization pattern

consisted of a 20-nm Ti layer followed by a 80-nm Au layer. The

center-to-center separation between IDTs was 48

µ

λ

with an aperture

of 700

m

which results in the largest electromechanical coupling coefficient

for this structure. For our device, the 36° Y-cut, X-propagation

LiTaO

µ

m. The thickness of sputtered ZnO guiding layer was 1.2

µ

substrate allows the propagation of shear waves. The shear

3