Biomedical Engineering Reference

In-Depth Information

the SEM image of the PPy matrix, SWCNTs bundles filler with

a diameter of 20 nm, and SWCNT/PPy nanocomposite. This

nanocomposite showed a better sensitivity to NO

gas than both

pure materials of SWCNTs and PPy that was due to the enhanced

conductivity of the composite material by dispersed CNTs. This PPy-

NT nanocomposite sensor exhibited signal degradation under long

time exposure.

2

. [177] fabricated a nanocomposite of MWCNTs

embedded in poly(2,5-dimethylaniline) (PDMA) by oxidative

polymerization. The nanocomposite PDMA-MWCNTs showed

a progressive spontaneous undoping process along the time

associated to the instability of the doping agent, constituted by HCl

vapors, inside the polymeric matrix. The instability of doping process

allowed to fabricate a spontaneous reversible sensor for acid vapors

by setting up a comparative potentiometric circuit and engineering

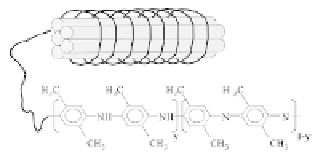

the sensitive element directly onto a circuit board. Figure 9.19 shows

the schematic of PDMA conducting polymer wrapped up around

MWCNTs, and the scheme of doping process of PDMA-MWCNTs

composite.

Bavastrello

et al

(a)

(b)

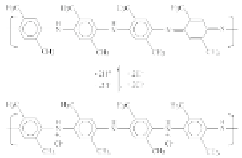

Figure 9.19

(a) Schematic of PDMA conducting polymer-wrapped

MWCNT film. (b) Scheme of reaction of the doping process of

the PDMA-MWCNT nanocomposite. This figure is reprinted

and adapted with permission from Elsevier [177].

. [178] developed composite thin film of poly-

methylmethacrylate (PMMA) with unmodified MWCNTs or

oxidation-modified MWCNTs (f-CNTs) as nanofillers for gas sensing.

The resistance changes of both nanocomposites were evaluated

upon exposure toward different gases including dichloromethane,

chloroform, acetone, and other volatile organic compounds. Both

CNT/PMMA and f-CNT/PMMA composites showed increasing

resistance upon exposure to these vapors at room temperature. This

Philip

et al