Biomedical Engineering Reference

In-Depth Information

(sample S-1), and reflects the substantially different structure of

the oxygen-containing groups. This signal has practically identical

position (1800-1810 cm

-1

) after thermal oxidation regardless of the

type of UDD.

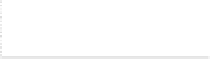

The TDMS method can be successfully used for determining the

optimum regime (temperature and duration) of thermal oxidation

of UDD and for checking the state of the oxidized surface. Figure 6.8

demonstrates the variations of the profiles of thermal desorption

of CO and CO

with the temperature of oxidation in air during

40 minutes for sample CH-7. The noticeable modification of surface

(increase in the desorption rate of CO

2

and CO near 600°C) is

observed at oxidation temperature as low as 300°C (Fig. 6.8, curve 3).

The main changes in the desorption profiles occur in the range

of 300-400°C. A further rising of oxidation temperature must be

avoided because of the possible losses of material (combustion) and

the increase in the concentration of nonvolatile impurities (metals,

etc.) on the surface due to the combustion of diamond.

The thermal oxidation in air seems to be an effective way to

unify the surface properties of various UDD and certainly is more

environment-friendly than acid treatment or the modification by

ozone [39, 40]. The additional advantage of thermal oxidation could

be the removal of non-diamond carbon from UDD as shown in

Ref. [77].

2

565

o

530

o

760

o

CO

CO

2

5

5

4

4

3

3

2

2

1

1

0

200

400

600

800

1000

0

200

400

600

800

1000 1200

TEMPERATURE,

o

C

Figure 6.8

Temperature profiles of CO and CO

release from UDD

CH-7 after heating in air at different temperatures: (1) without

heating; (2) heating temperature 200°C; (3) 300°C; (4) 400°C;

and (5) 450°C.

2