Biomedical Engineering Reference

In-Depth Information

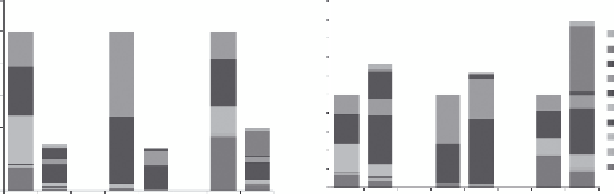

according to the environmental impacts per mass. The use of popcorn pack-

aging results in fewer emissions per mass over its life cycle, making it three

to four time less damaging than polystyrene, according to the chosen impact

weighting method (Figure 11.3a). However, the comparison should be based

on the function of this material rather than on its weight. The function of

packaging is to occupy volume. Since popcorn is 4.6 times denser than poly-

styrene peanuts, more mass is needed to fill the same volume, making pop-

corn comparable to or less environmentally friendly than polystyrene on a

per volume basis (Figure 11.3b).

On the basis of this analysis, key parameters can be identified to guide

future decisions on reducing impacts of packaging materials. Initially,

the key parameters for popcorn production appear to be the quantities

of nitrates and fertilizers used for growth, of diesel used for tractors, or

of gas used to make the popcorn, as these are all major sources of key

emissions and subsequent impacts. This analysis shows that due to the

function of this product, the key parameter is actually the density of the

materials. The industrial process of extracting starch and blowing it into

polystyrene results in more chemical emissions per mass than popcorn,

but it is able to sufficiently decrease the key parameter of density to make

the impacts of the more industrial product comparable or even less than

those of the “natural” one. This example shows the importance of con-

sidering the product function as the basis for comparing products. It also

shows the potentially existing synergy between technological optimiza-

tion (here the reduction of weight and of used material quantity) and ener-

getic and environmental optimization.

How does the classic and standardized LCA approach apply to the spe-

cific of a nano-based product?—that is the question addressed in our next

section!

120%

200%

180%

160%

140%

120%

100%

80%

60%

40%

20%

0%

(b) Impact per m

3

material

(a) Impact per kg material

100%

Phosphates

Nitrates

NH

3

SO

2

NO

x

HC

CO

Part.

N

2

O

CO

2

80%

60%

40%

20%

0%

PS

PS

PS

PC

PC

PC

PS

PC

PS

PC

PS

PC

Swiss ecopoints

Critical volume Crit. surface-time

Swiss ecopoints

Critical volume Crit. surface-time

FIGURE 11.3

Comparison of impacts of popcorn (PC) packaging versus polystyrene (PS) packaging on per

kilogram basis (a) and per volume basis (b). Impacts are weighted according to three impact

assessment methods (critical volume, critical surface-time, and Swiss ecopoints methods).

(From Jolliet, O. et al.,

Agric. Ecosyst. Environ.

,

49,

253, 1994.)