Biomedical Engineering Reference

In-Depth Information

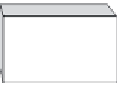

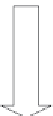

Heat

recovery

Steam

system

Steam

Natural

gas

Feed gas

purification

Steam

reforming

Reformed

gas

Heat

recovery

Feed gas

Natural gas

Refined

methanol

Distillation

Crude methanol

Methanol synthesis

Syngas

Compression

FIGURE 1.1 Conventional methanol production.

hydrocarbons producing a synthesis gas of carbon dioxide and hydro-

gen; (3) methanol synthesis by passing the synthesis gas over a

catalyst bed at high temperatures and pressures to produce crude

liquid methanol; and (4) distillation typically accomplished in a two-

step process to remove water and some ethanol created in the process.

The finished methanol must meet rigorous purity standards generally

in the order of 99.85% (ASTM D-1152/97).

The production of methanol from natural gas, coal, or biomass shares

a number of basic processing steps (Zuberbuhler, 2005). The feedstock

must be gasified by heating in the presence of little or no oxygen to

produce a synthesis gas made up of carbon monoxide, hydrogen, carbon

dioxide, and water (along with various other gases). This “syngas” is

then catalytically processed into liquid methanol while much of the

“equipment” for gasification involves mature technologies using rec-

ognized feedstocks. While majority of methanol is produced through

the steam reformation of natural gas, China has focused on converting

its vast coal resources to methanol via gasification. For “biomethanol,”

the immature part of the equation is the first step, the gasification of

biomass (a feedstock with different characteristics). Once the syngas is