Information Technology Reference

In-Depth Information

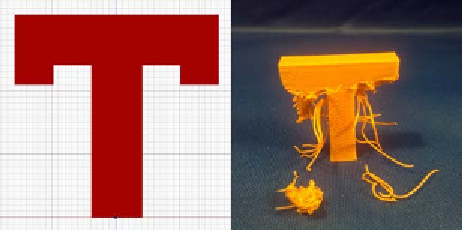

Because of this layer-by-layer process, if a design is made so that any part has

nothing underneath it, dangling in the air, then the printer will still extrude some

plastic to try to print the part which will just dangle from the nozzle and be dragged

into the next area where it will build up an ugly mess and ruin the print:

Building for supportless prints

One way of fixing the dangling object problem is to configure the preparing software

to build the model "with supports". This means the slicer will automatically build a

support lattice of plastic, up to the dangling part so that it has something to print on.

Higher-end printers can actually print with a different material that can be dissolved

away, but so far most home printers only use break-away supports. Either way after

the print is complete it is left to the user to clean up this support material to extract

the desired part.

While supports do allow the creation of objects that would be impossible any

other way, the supports themselves are a waste of material and often don't remove

cleanly leading to a messy bottom surface where they contact the print. If a part

is designed needing supports that are hard to remove, such as if they're internal

and partially obscured, it can be difficult and frustrating to completely remove the

support material (this can be true for even the higher-end 3D printers). The process

of removing it may actually damage the print.