Agriculture Reference

In-Depth Information

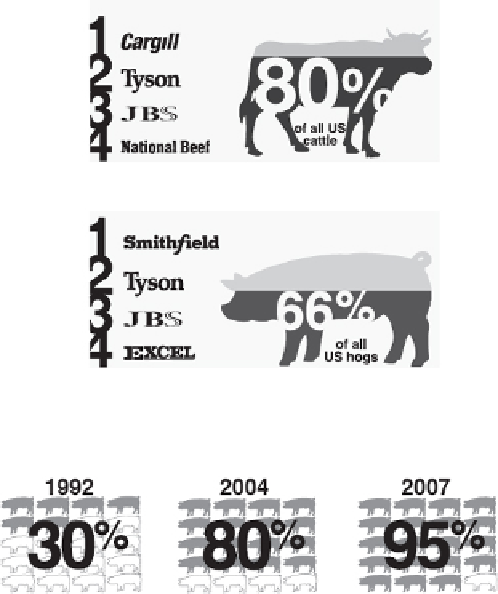

change in percentage of hogs that are raised on

factory farms

(more than 2,000 animals)

This debt makes the hog factory operator extremely dependent on the cash from the operation to pay

back the loans they have taken out for building and upgrading facilities. Operators that rely on a steady

contract relationship with a packer or processor are unable to complain about shoddy treatment or unfair

terms for fear of retaliation that could end their business.

8

The terms for hog production contracts can significantly disadvantage producers. Some provide a strict

management manual for growers, eliminating the producer's autonomy to make decisions.

9

Operators are

also responsible for securing permits for manure disposal and for taking on the environmental liability as-

sociated with it.

10

Some contracts even have a provision that allows the pork packer to evict farmers from

their own hog barns and force them to hire company-selected managers to finish if the packer decides that

the farmer was not properly caring for the livestock.

11

In many cases the companies use the contracting

process to force factory operators to increase the scale of their operations or lose the sales.

Unfortunately, a window of opportunity for tackling contract abuses was lost in the fall of 2011, as de-

scribed in the previous chapter, when the Obama administration capitulated to the meat industry and failed

to reform the rules.

12

Reforming these GIPSA regulations has been at the top of the agenda for many hog producers for many

years. Chris Peterson, a farmer from Clear Lake, Iowa, and president of the Iowa Farmers Union, views

the packer ownership and control of hogs through contracts as the major impediment to the return of a

level playing field for farmers. At the 2010 USDA/DOJ joint hearings held in connection with revising

the GIPSA rules, Peterson testified in support of them. He said that when he started raising hogs in the

Search WWH ::

Custom Search