Environmental Engineering Reference

In-Depth Information

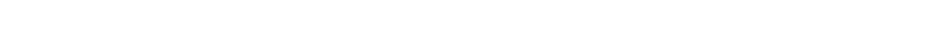

Table 16-2.

Loss categories and typical values

Loss category

Low

Typical

High

Wake effects, %

3

6.7

15

Availability, %

2

6.0

10

Electrical, %

2

2.1

3

Turbine performance, %

0

2.5

5

Environmental, %

1

2.6

6

Curtailments, %

0

0

5

Total losses, %

7.8

18.5

37.0

The ranges apply to plants in mature operation; losses, especially availability losses, may be greater in the

first 6-12 months after construction. Some plants may have smaller or larger losses than indicated here.

The total loss is the product of the efficiencies; see Equation 16.4.

Source:

AWS Truepower.

to be greater in the first 6-12 months of operation as problems are identified and

resolved. Turbine performance, too, can change over time as turbine components such

as blades become worn and pitted.

16.6.1 Wake Effects

This is the reduction in wind speed and increase in turbulence that occurs downstream

of a wind turbine. In projects involving more than a handful of turbines, wake effects

typically reduce power production by anywhere from 3% to 15%. Keeping this loss

manageable is the main reason turbines are rarely spaced closer than 6 rotor diameters

in the prevailing wind direction. Furthermore, wake-induced turbulence can cause

wear on the components of turbines, and for this reason, turbines are usually spaced

no closer than 3 rotor diameters in crosswind directions, and they may have to be shut

down under certain conditions to satisfy the manufacturer's warranty.

Since wake effects change with the layout, all wind plant design software must

contain a wake model of some kind, and most have more than one. Three main

types in regular use are described later in this chapter: the Park and modified Park

model, the eddy viscosity (EV) model, and the deep-array (or large-array) wake model.

Other models based on CFD and LES (large-eddy simulation) codes, which are under

development, are outside the scope of this topic.

16.6.2 Downtime

A wind plant or turbine is said to be available when it is capable of generating its

full rated output, given sufficient wind. Availability losses occur when some turbines

in a project, or the entire project, are inoperative for some reason. They can also

occur because of a failure or shutdown of the power grid or substation. An overall

plant availability of 97-98% (2-3% loss) is frequently assumed in energy production

studies, but is likely to be optimistic unless there is good evidence that the plant

operator has regularly achieved such high performance with the turbine model in

question. Plant start-up problems, repair delays, fleet-wide turbine issues requiring

Search WWH ::

Custom Search